In manufacturing, quality needs to be built into every step of production. From materials to final assembly, consistent quality control ensures products meet standards, reduce waste, and protect your brand’s reputation.

Manufacturers succeed when quality control is systematic and data-driven. By combining inspections, audits, and real-time tracking, businesses gain the visibility to get ahead of issues before they happen. 👀

Here at Method CRM, we’ve been supporting QuickBooks-based businesses since 2010. Method is loved by business owners in the manufacturing sector for its two-way QuickBooks sync, customization services, and end-to-end sales automation. 🔄📈

In this article, we’ll show you how to implement quality control in manufacturing so your production processes consistently deliver high-quality finished products and satisfy your customers, too. 🚀

Table of Contents

- What is quality control in manufacturing? 🤔

- Why quality control matters in manufacturing 💡

- Key elements of a manufacturing quality control system 🧩

- Quality control methods and tools ✍

- Implementing an effective quality control framework: Step-by-step ✅

- 1. Map your production process

- 2. Define quality requirements and metrics

- 3. Build your quality management system

- 4. Choose and deploy tools

- 5. Train and empower staff

- 6. Monitor and respond in real time

- 7. Conduct root cause analysis and corrective actions

- 8. Review and improve

- 9. Maintain traceability and audit suppliers

- 10. Align with standards and certifications

- Key metrics and benchmarks 📊

- Common challenges and how to avoid them ⚠️

- The role of quality control in achieving continuous improvement and excellence 🏆

- Why choose Method CRM for quality control in manufacturing? 🧐

- Summary 📝

What is quality control in manufacturing? 🤔

Quality control in manufacturing is the process of ensuring every product meets defined standards. It focuses on inspecting and testing throughout production to catch defects early and keep everything within specification.

Each product and process follows measurable standards, including tolerances, dimensions, functionality, and performance benchmarks, aligned with customer and regulatory requirements.

Quality control teams test raw materials, components, and finished goods against those expectations. Done well, this reduces waste, limits rework, and protects your brand’s reputation.

Quality control is one part of a larger quality system that includes quality assurance, the preventive side of quality management. Quality assurance ensures the right processes, documentation, and training are in place, while quality control confirms that the results meet requirements.

Together, they form the backbone of a Quality Management System such as ISO 9001, which promotes consistency, accountability, and continuous improvement.

Since manufacturing involves multiple steps and high output, quality control must occur at several points: during material intake, throughout production, and on the final product.

This layered approach helps ensure every item leaving your facility is compliant, safe, and ready for your customers.

Why quality control matters in manufacturing 💡

Quality control directly affects profitability, efficiency, and brand trust.

- Poor quality costs money: Without proper quality control, manufacturers face higher scrap rates, additional labor, and disrupted schedules. Early detection and prevention save both time and cost thanks to production lines running smoothly.

- Quality control protects your reputation: Defective products lead to returns, recalls, and unhappy customers. Reliable quality control processes prevent this and build confidence. This is crucial in sectors like automotive or medical manufacturing, where a single defect creates serious safety or financial consequences.

- Compliance and risk management: Strong quality control systems maintain the documentation and traceability required by ISO 9001 or FDA regulations. Proper records simplify recalls, demonstrate due diligence, and make certification easier, often a deciding factor for customers choosing a supplier.

- Competitive advantage: Consistent quality creates loyal customers and often allows higher pricing. When products perform reliably, your brand stands out in crowded markets.

Key elements of a manufacturing quality control system 🧩

Rather than just inspecting the final product, quality control is a whole system that defines what “good quality” is and makes sure every stage of production contributes to that outcome.

Here are six of the core components:

- Defining quality standards and requirements: Establish clear, measurable standards for materials, processes, and end products (including supplier and manufacturing process parameters) to provide a foundation for consistent quality.

- Integrating quality assurance and quality management systems: Combine quality control, quality assurance, and a quality management system like ISO 9001 to create a unified, documented approach that ensures prevention, detection, and continuous improvement.

- Production process controls and monitoring: Use tools such as SPC, sensors, and real-time monitoring to detect variation early and maintain process stability, reducing waste and rework.

- Final product inspection and verification: Perform final inspections or sampling to confirm compliance and reliability, using them as a safeguard alongside in-process controls.

- Continuous improvement and audits: Strengthen quality over time through root cause analysis, data-driven reviews, and regular audits that verify compliance and drive improvement.

- Traceability, automation, and technology in quality control: Link every stage of production with traceable data and automation tools to improve visibility, accelerate problem-solving, and ensure consistent product quality.

Quality control methods and tools ✍

Manufacturers rely on a range of quality control methods to maintain consistency and minimize defects.

Here are the most widely used approaches:

- Statistical Process Control (SPC): Uses real-time data and control charts to monitor process variation. Detects issues early so operators can adjust before defects occur.

- Six Sigma, Lean, and TQM: Six Sigma’s DMAIC process reduces variation; Lean eliminates waste; and Total Quality Management (TQM) builds a company-wide commitment to quality. Used together, they create efficient, reliable processes.

- Inspection and acceptance sampling: Inspections verify quality at incoming, in-process, and final stages. When inspecting every unit isn’t feasible, sampling provides an efficient way to assess quality statistically while managing risk.

- Automation and real-time monitoring: Sensors, cameras, and digital dashboards detect issues instantly. This reduces human error and creates a steady flow of quality data for analysis.

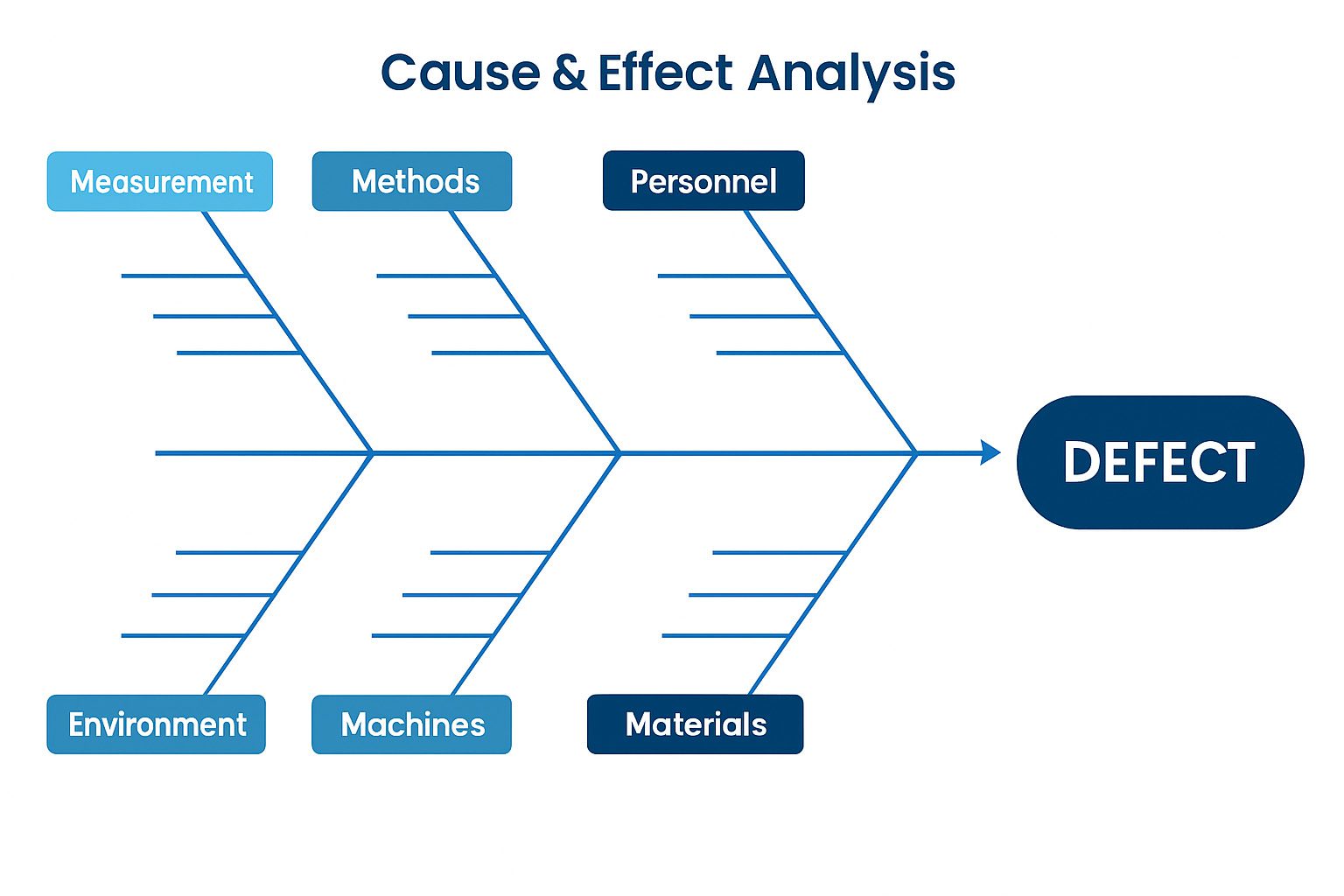

- Root cause analysis and corrective actions: When defects occur, structured tools such as the 5 Whys or fishbone diagrams uncover true causes. Corrective and preventive actions (CAPA) ensure problems don’t recur and the system keeps improving.

Implementing an effective quality control framework: Step-by-step ✅

Setting up or improving a quality control framework in manufacturing can seem daunting, but it helps to break it down into clear steps.

Below is a step-by-step approach that can guide you through building a robust quality control system from the ground up:

1. Map your production process

Outline your entire workflow (from raw materials to finished goods) and identify potential sources of variation. These become your control points.

2. Define quality requirements and metrics

Set measurable goals for defect rates, yield, and first-pass success. Clear metrics make performance easier to track and improve.

3. Build your quality management system

Document procedures, assign responsibilities, and ensure everyone knows their role in maintaining quality. For ISO 9001 certification, include recordkeeping, audits, and management reviews.

4. Choose and deploy tools

Equip control points with appropriate inspection tools, sensors, and sampling plans. Maintain reliable data collection—manual or digital—for analysis and traceability.

5. Train and empower staff

Provide hands-on training and explain why procedures matter. Encourage everyone to take ownership of quality and report issues immediately.

6. Monitor and respond in real time

Use dashboards or inspection sheets to continuously track data. Act fast when variations occur to prevent costly rework or downtime.

7. Conduct root cause analysis and corrective actions

Investigate defects deeply rather than just patching symptoms. Implement corrective actions and verify their success.

8. Review and improve

Hold regular reviews of audit results and metrics. Use insights to refine processes, equipment, and training.

9. Maintain traceability and audit suppliers

Keep detailed records of production and inspection data. Audit internal processes and supplier performance to ensure alignment.

10. Align with standards and certifications

Follow frameworks such as ISO 9001 or industry-specific standards (e.g., IATF 16949 for automotive, ISO 13485 for medical). Certification ensures consistency and builds customer trust.

Key metrics and benchmarks 📊

To manage quality control, you have to measure it. Manufacturers track several key metrics and benchmarks to gauge how their quality control processes are performing.

Below are some of the most widely used ones:

- Defects Per Million Opportunities (DPMO)

- First Pass Yield (FPY)

- Scrap and Rework Rate

- Defect Rate (or Yield)

- Process Capability (Cp, Cpk)

- Cost of Quality (CoQ)

- Customer Returns and Warranty Claims

- Audit Findings

- Supplier Defect Rate

- Inspection Coverage and Efficiency

The key is not to drown in metrics, but to choose a handful that best reflect your quality performance and business priorities, and use them to guide decisions.

Common challenges and how to avoid them ⚠️

Even with a solid quality control plan, manufacturing teams frequently encounter pitfalls. Being aware of these challenges can help you proactively avoid them.

Here are some common issues in manufacturing quality control, along with a strategy to address them:

- Over-reliance on final inspection: Treat final inspection as a safeguard rather than your primary quality method.

- Poor traceability of materials and parts: Good records allow faster root cause analysis and limit the scope of recalls.

- Lack of real-time monitoring: Real-time monitoring, whether through sensors or SPC charts, helps detect process deviations immediately, reducing scrap and rework.

- Inadequate training and quality culture: Provide training that explains both the ‘how’ and the ‘why’ of tasks. Reinforce a culture where quality and safety are valued as much as output, and recognize workers who identify or prevent issues.

- Not linking quality control to business outcomes: Report metrics that connect quality to savings and customer satisfaction, such as reduced scrap costs or lower return rates.

- Data silos and lack of analysis: Centralize your quality data and regularly review it for trends and correlations.

- Ignoring supplier quality issues: Strengthening supplier quality prevents downstream problems.

- Undefined metrics and unclear benchmarks: Track progress and celebrate milestones to maintain momentum.

- Misalignment with standards or customer requirements: Aligning with recognized standards brings structure, consistency, and credibility to your quality program.

The theme across most solutions is being proactive, whether it’s catching issues early, preventing them by design, engaging people in quality, or systematically measuring and improving.

The role of quality control in achieving continuous improvement and excellence 🏆

Quality control fuels continuous improvement because it provides the feedback loop manufacturers need to make further changes. Through the Plan-Do-Check-Act cycle, quality control drives data-based decisions and prioritizes the areas with the biggest impact.

Quality control data also provides the foundation upon which Lean and Six Sigma changes are identified, validated, and sustained by the teams. Over time, the consistent attention to quality instills a culture of accountability and pride.

Quality control also influences design and innovation. Data from inspections enables engineers to develop products that are easier to make and can meet customer expectations more reliably.

Finally, quality control metrics stand alongside financial and delivery KPIs as indicators of operational excellence: consistent quality reflects strong management, engaged employees, and well-run systems.

Why choose Method CRM for quality control in manufacturing? 🧐

Implementing quality control often involves managing data, teams, and processes, and this is where Method CRM is a game-changer for business owners in the manufacturing sector.

Method’s flexibility and QuickBooks integration make it a powerful tool for quality management.

- Custom quality control workflows: Build custom screens for inspections, audits, or non-conformance reports linked to job orders or inventory in QuickBooks.

- Real-time dashboards: Display metrics like defect rates, scrap costs, and first-pass yield for instant visibility.

- Root cause and corrective action tracking: Log quality issues, assign tasks, and track resolutions through Method’s Activities app.

- Audit trail and traceability: Every record is time-stamped and linked to users, providing transparency and compliance support.

- Supplier and production linkage: Integrate quality control data with supplier, product, and financial records for a unified view of performance.

Method CRM serves as a flexible backbone for your quality control program — organizing data, connecting departments, and ensuring visibility across your operation.

Summary 📝

Quality control ensures every product meets your company’s and customers’ expectations. It starts with clear standards, continues through active monitoring, and extends beyond production through ongoing improvement.

Strong quality control reduces costs, increases efficiency, and builds trust through consistent quality.

Key takeaways 💬

Here’s a quick recap of six of your key takeaways:

- Quality control vs. quality assurance: Quality control checks and verifies; quality assurance prevents and designs for quality.

- Why it matters: Consistent quality lowers costs, maintains compliance, and strengthens brand reputation.

- Core elements: Clear standards, process controls, final inspection, audits, and traceability.

- Methods: SPC, Six Sigma, and Lean streamline operations and reduce variability.

- Implementation: A step-by-step plan ensures structure, accountability, and measurable progress.

- Common pitfalls: Overreliance on inspection, weak use of data, and poor supplier oversight.

Quality control is an ongoing process, not a one-time effort. Manufacturers that treat quality control as a core part of operations achieve greater efficiency, reliability, and customer loyalty. 🤝

With the right systems, data, and culture, consistent quality becomes a long-term competitive advantage. 🎯

Ready to see how Method CRM can support your manufacturing quality goals?