Best manufacturing process automation software in 2026

In order to stay ahead of the competition, manufacturers must constantly seek innovative ways to:

- Improve manufacturing operations.

- Reduce costs.

- Increase efficiency.

One of the most effective ways to achieve this is to implement manufacturing process automation software.

In this guide, you’ll explore:

- Several benefits of automated manufacturing systems.

- The top five manufacturing process automation software in 2026.

- How to choose the perfect solution to propel your business forward.

Let’s jump into everything you need to know about manufacturing process automation software.

What are automated manufacturing systems?

Automated manufacturing systems simplify production by using manufacturing process automation software. This software reduces reliance on manual labor and frees up time for high-value tasks.

Manufacturing software:

- Optimizes operations.

- Enhances productivity.

- Controls equipment and processes.

As a result, it improves your efficiency and output quality.

Let’s look at what you stand to gain when you automate your manufacturing processes.

The different types of automation technologies in the manufacturing industry

Procurement

Automation in procurement involves the use of technology to streamline the procurement process. This includes:

- Automating the selection and purchasing of raw materials and services.

- Managing supplier relationships.

- Ensuring compliance with company policies and regulations.

Advanced systems can predict needs to manage inventory levels, and even negotiate pricing, all with minimal human intervention.

Order processing

In order processing, automation technologies enhance the efficiency and accuracy of handling customer orders. From the moment an order is placed, automation systems can track its progress, update inventory, and manage billing and shipping processes. These systems reduce manual errors, speed up order fulfillment, and improve customer satisfaction.

Supply chain

Supply chain automation uses technology to manage and coordinate the various activities involved in producing and delivering goods. This includes inventory management, logistics, transportation, and warehouse operations.

Automation in the supply chain:

- Ensures a seamless flow of materials and product

- Reduces costs.

- Improves overall efficiency in the manufacturing process.

Benefits of automated manufacturing processes

Automated manufacturing processes, powered by your manufacturing process automation software, offer numerous advantages that transform your operations.

Reduce labor costs and production waste

Manufacturing process automation provides cost savings by reducing manual labor requirements and simplifying operations.

Additionally, by ensuring the right manufacturing process and efficiently managing raw materials, your automation system lowers production waste. It enhances accuracy and optimizes resource usage.

Faster response times

Automation in manufacturing systems improves customer service and order response times to handle fluctuations in demand. As a result, it ensures timely production adjustments.

These systems help you analyze data in real time and make quick, informed decisions. This enhances agility and adaptability.

Optimize your production rates and efficiency

Automation in manufacturing also optimizes production rates and efficiency throughout your business processes. This maximizes your output while maintaining quality standards and meeting customer expectations.

Take repetitive tasks off your plate

Automated manufacturing systems involve smart manufacturing tools as they handle repetitive tasks. This frees up your team to focus on value-added activities.

By automating mundane tasks in your production process, you also boost employee satisfaction and reduce the risk of human error.

Essential features of manufacturing process automation software

Selecting the right manufacturing process automation software is crucial to achieving the full benefits of an automated manufacturing system.

To help you make the most informed decision, here are some essential features to consider.

1. Scalability and flexibility

Choose manufacturing process automation software that easily scales and adapts to your business’ changing needs. Flexible automation supports seamless integration with your existing systems and accommodates future growth or adjustments in your production processes.

2. Real-time data and analytics

Real-time data and analytics capabilities are crucial for monitoring, controlling, and optimizing production processes. Your chosen software should provide comprehensive data analysis tools and visualizations to drive informed decision-making and continuous improvement.

3. User-friendly interface

An intuitive user interface is vital for smooth implementation and operation. Look for a solution with a clear, easy-to-navigate dashboard that simplifies complex tasks and reduces the learning curve for users.

4. Advanced scheduling and planning

Effective scheduling and planning features:

- Optimize production timelines.

- Minimize delays.

- Maximize resource utilization.

Your chosen software should allow for precise scheduling, considering factors like: m

- Machine availability.

- Labor.

- Material constraints.

5. Robust security and compliance

Ensure that your manufacturing process automation and standardization adhere to industry-specific security and compliance regulations. Your system should protect sensitive data and support secure communication protocols to prevent unauthorized access and potential cyber threats.

Now that you know which features to look for, let’s go over your top five manufacturing process automation options.

Top 5 manufacturing process automation software

1. Method

First on our list of the top manufacturing process automation software is Method. It’s an ideal solution for managing manufacturing and accounting processes due to its seamless two-way sync with QuickBooks and Xero.

This integration ensures smooth data flow and collaboration across the shop floor and sales office alike.

Method also offers detailed customer history that helps you deliver exceptional service, as well as custom reports to inform future strategies.

With Method’s automation capabilities, creating work orders becomes effortless. You can accurately track critical details and convert work orders into error-free invoices in just a few clicks.

Key Features

- Effortless two-way integration with QuickBooks or Xero.

- Time tracking for simplified payroll management.

- Self-service online portals for your customers.

- Mobile app for shop floor managers on the go.

- Native integrations with Gmail, Outlook, Paypal, Zapier, and more.

Pros

- Smooth data flow between Method and your accounting software.

- Limitless customization using no-code, drag-and-drop tools.

- Easy work order-to-invoice conversion with a single click.

- Personalized templates for email campaigns, reports, and transaction documents.

Cons

Method is best suited for QuickBooks or Xero users and is currently only available in English.

Pricing

Method offers three subscription options:

- Contact Management: $27 per user per month.

- CRM Pro: $45 per user per month.

- CRM Enterprise: $73 per user per month.

You can try Method for free, no credit card required.

2. Katana MRP

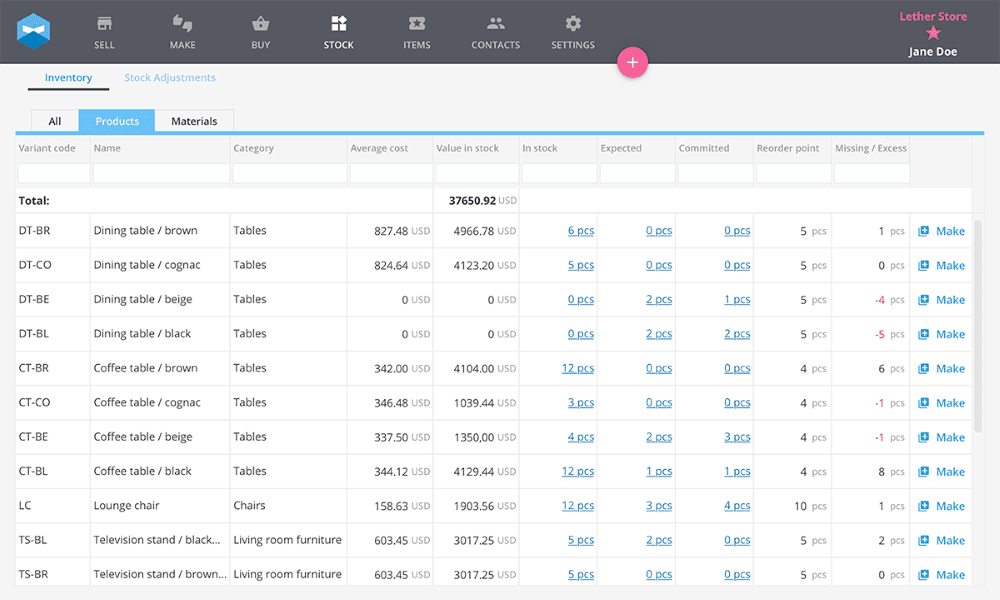

Image credit: Katana

Katana is a cloud-based MRP manufacturing platform tailored for small businesses. It offers modules for:

- Production planning.

- Inventory management.

- Order and purchase management.

Its Shop Floor App provides real-time insights that let you track manufacturing costs based on your production operations.

Key features

- Production planning and scheduling.

- Real-time inventory management.

- Centralized dashboard for sales order management.

- Integrations with Shopify, QuickBooks, Xero, and more.

Pros

- Clean visual interface for effortless progress tracking.

- Monitors manufacturing costs based on BoM and production operations.

Cons

Katana lacks key manufacturing features like shipping supply tracking and may be too costly for small businesses.

Pricing

Katana offers three pricing plans:

- Essential: $99 per user per month.

- Advanced: $299 per user per month, and includes 3 shop floor operators.

- Professional: $799 per user per month, and includes 3 shop floor operators.

3. L2L

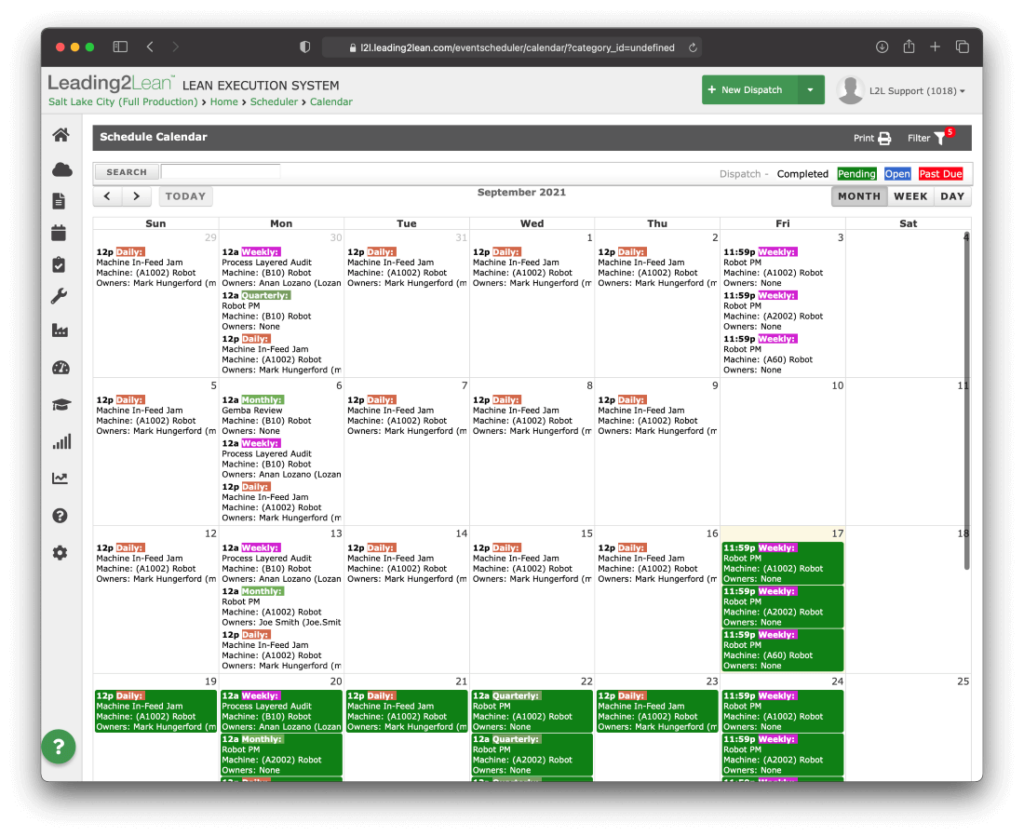

Image credit: L2L

L2L (Leading2Lean) is a cloud-based manufacturing software focusing on lean manufacturing principles that improve operational efficiency and reduce waste.

L2L offers real-time data and performance tracking, which let businesses make informed decisions and optimize processes.

Key features

- Production maintenance and management tools.

- Work order management and scheduling.

- Integrations with major ERP systems.

- Mobile access for shop floor insights.

Pros

- User-friendly interface for easy implementation.

- Emphasizes lean manufacturing principles to minimize waste.

- Real-time data helps you address issues quickly.

Cons

Some users report that recurrent system updates restrict operations. L2L’s native integrations are also fewer compared to similar solutions.

Pricing

L2L offers customized pricing based on individual business requirements.

4. Prodsmart

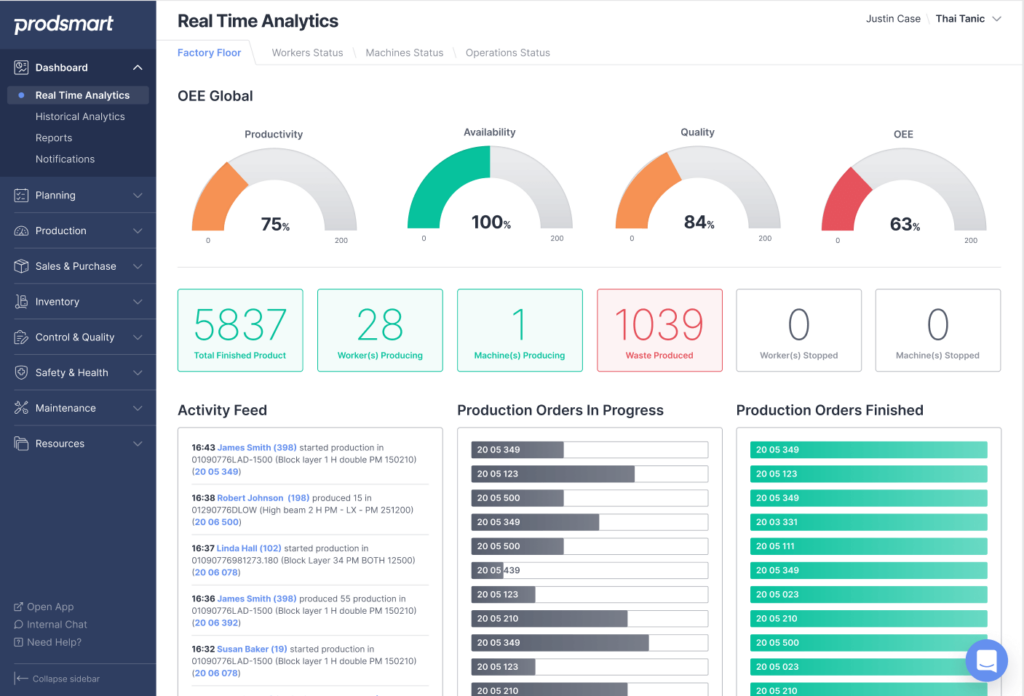

Image credit: Prodsmart

Prodsmart is an MES (manufacturing execution system) explicitly designed for fabricators and manufacturers. It offers a user-friendly solution to track and manage the entire production process, from sales to shipping.

With Prodsmart, manufacturers can:

- Monitor production progress.

- Pinpoint bottlenecks.

- Anticipate machine downtime.

- Reduce waste.

Key features

- Real-time operations and performance tracking.

- Material requirements planning and inventory management.

- Work order management and scheduling.

Pros

- Easy deployment with minimal setup.

- Accurate tracking and inventory overview.

- Responsive and effective customer support.

Cons

Some users have pointed out a lack of must-have warehouse management system features.

Pricing

Prodsmart has a single annual pricing plan at $9,925 per year.

5. Syteline

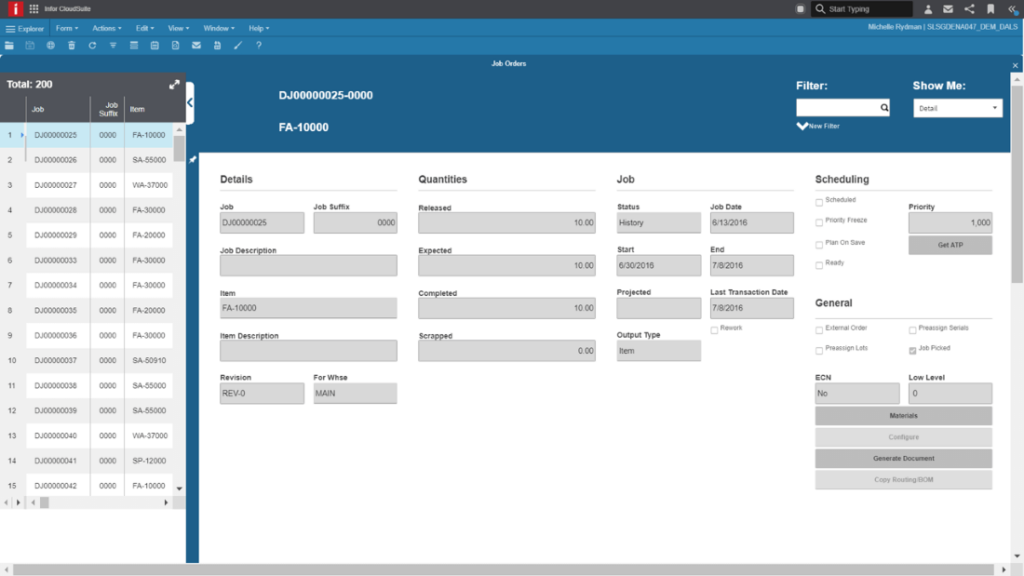

Image credit: Infor Syteline

Syteline, also known as Infor CloudSuite Industrial, is a comprehensive ERP solution designed for manufacturers and distributors.

It provides robust functionality to simplify manufacturing processes and facilitate informed decision-making.

Key features

- End-to-end manufacturing and distribution management.

- Advanced operations planning and scheduling tools.

- Supply chain management and real-time analytics.

Pros

- Intuitive and accessible cloud-based solution.

- Comprehensive functionality for manufacturers and distributors

- Seamless integration with other Infor products and financial systems.

Cons

Users have reported lengthy and costly implementation, as well as slow loading speeds. Some have also pointed out significant reporting limitations.

Pricing

Syteline offers custom pricing based on business size and requirements.

Recap: How to embrace manufacturing process automation in your business

Manufacturing process automation software has become indispensable for businesses seeking to:

- Enhance efficiency.

- Reduce costs.

- Stay ahead in the manufacturing industry.

By leveraging the benefits of automated manufacturing systems, you optimize production, improve response times, and reduce waste — ultimately driving growth and profitability.

As you evaluate your options, focus on essential features such as:

- Scalability.

- Real-time data analytics.

- User-friendly interface.

- Advanced scheduling.

- Robust security.

If you’re a QuickBooks or Xero user, Method is the ideal solution for your operations. With its seamless connection with QuickBooks and Xero and advanced features, Method simplifies your workflows and grows your business, not your stress.

In the video below, check out how an integration with Method helped double this shipping container company’s revenue in just three years.

Automated manufacturing system FAQs

How does automation in manufacturing work?

Manufacturing automation uses technology like robotics and software to control production processes, which minimizes human input. It enhances efficiency, consistency, and speed in tasks such as assembly and quality control.

What is industrial automation?

Industrial automation involves using computers and robots to manage industrial processes. It increases efficiency and quality while reducing human intervention and labor costs. It’s essential

in sectors like automotive and electronics for precision and consistency.

Free yourself from the chaos of your day-to-day operations with your free trial Method!

Image credit: lifestylememory via freepik