A CRM is a must for any business that regularly deals with customers. But what’s most important is having the right CRM for your business.

CRMs are as unique as businesses, which makes it challenging to find the perfect match for your needs.

One solution to this problem is to learn how to build a custom CRM system for your business.

Whether you build this CRM or hire someone else to do it for you, there are a few things worth knowing before embarking on this adventure.

Keep reading to learn how to build a CRM system to:

- Optimize your workflows.

- Improve customer service.

- Strengthen your sales.

As a bonus, you’ll discover alternatives to building your own CRM that still provide you with a personalized system.

What is a CRM?

You can’t understand how to build a CRM system if you don’t know what a CRM is.

CRM stands for customer relationship management and is a tool that improves how you interact with your customers.

With a CRM, you can:

- Organize your contacts.

- Simplify customer communications.

- Track every customer interaction.

No matter how small or large your company is, you need a CRM to trigger business growth and actively maintain it.

Let’s look at some statistics for context on where CRM software stands in today’s business world.

Stats on CRM systems usage

According to Martech, CRM is among the top three tools for creating personalized customer interactions to foster loyalty and a higher marketing return on investment (ROI).

Businesses can expect an estimated ROI of $8.71 for every dollar spent on CRM software.

This shows an increase from 2011, when the average ROI was just over $5.00. And that figure continues to increase as CRM technology becomes more advanced.

Finally, 91% of companies with ten or more employees use a CRM. So if your business fits this category, but you don’t yet use a CRM, you’re behind your competition.

CRM is at the heart of every growing business. Let’s check out the features that make this possible.

Key features of CRM systems

Knowing how to build a CRM system involves understanding the key features behind the system.

Here are three core features that all custom CRM software needs.

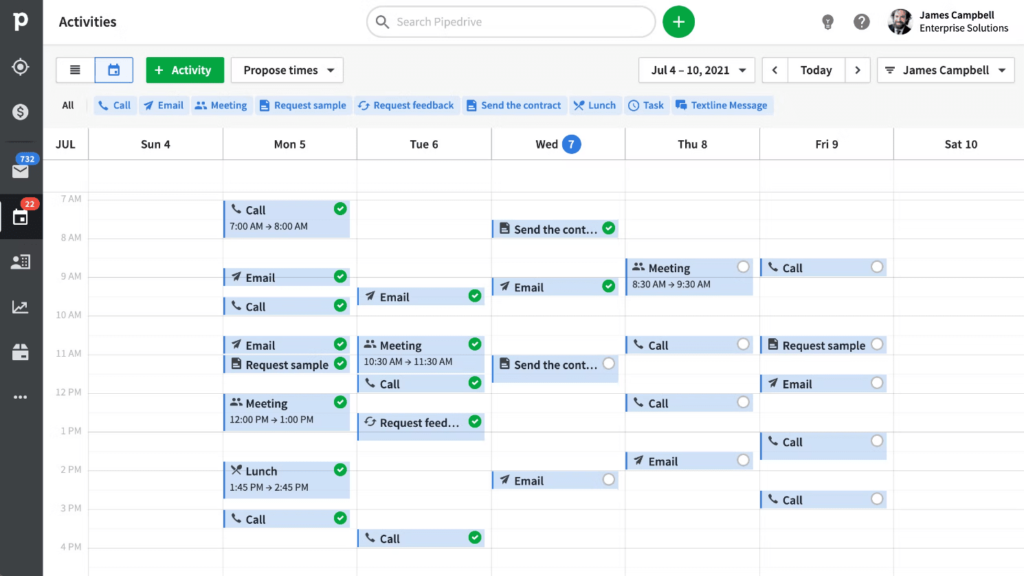

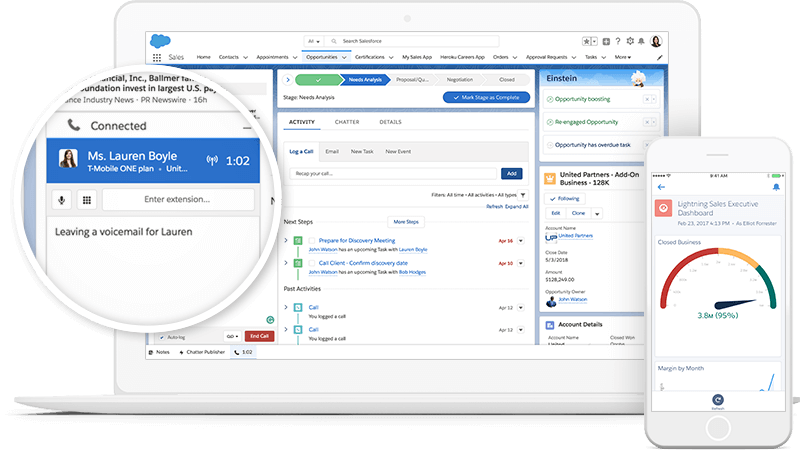

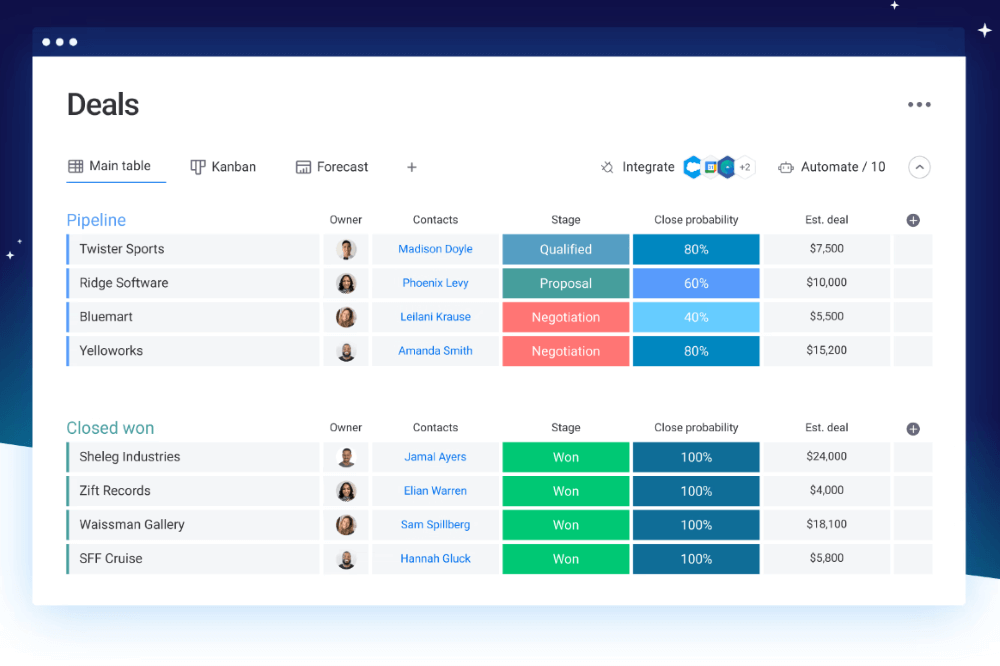

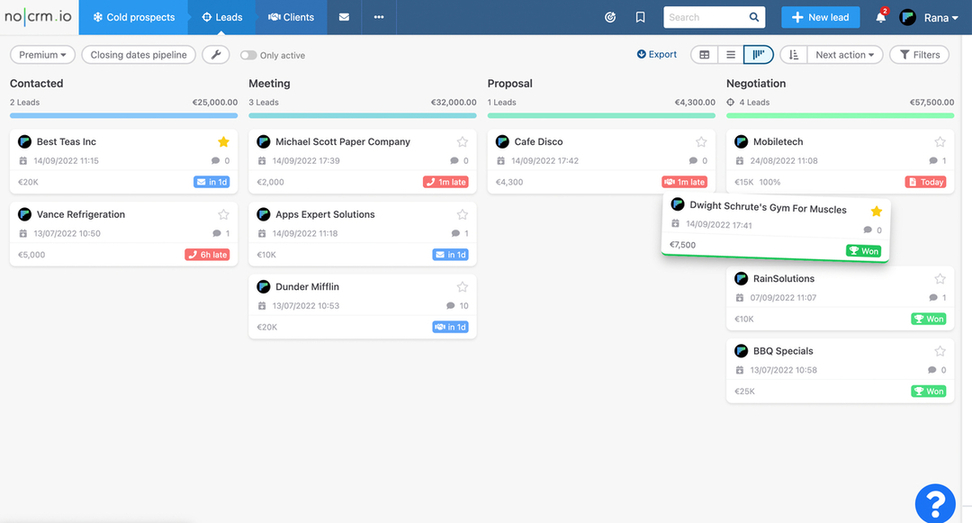

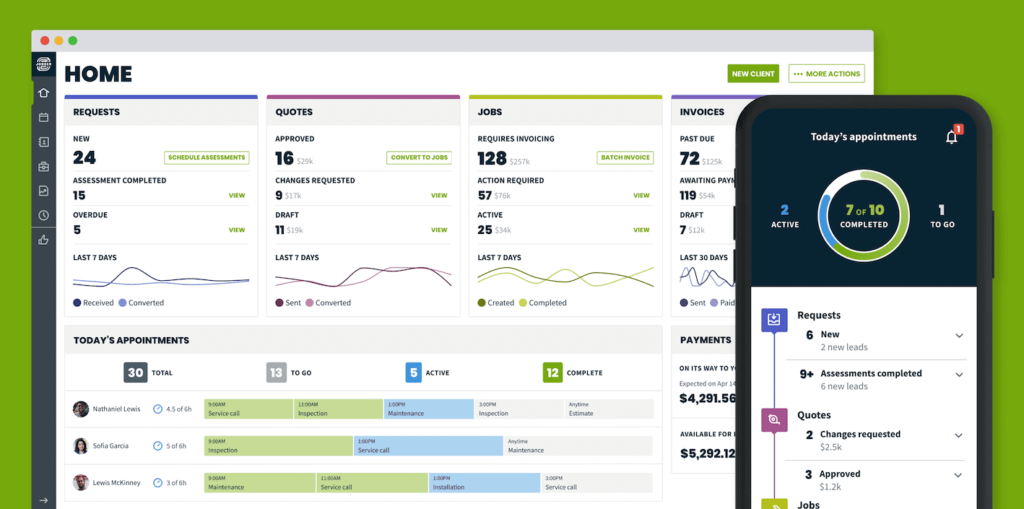

Sales features

Since a CRM focuses on managing your customers, you can expect your CRM system to become your sales team’s new best friend.

That’s why it’s crucial to ensure that your CRM has robust sales features, such as:

- Dashboards.

- Automated notifications.

- Sales analytics and reporting.

These features ensure that your sales representatives always have the information they need to excel at their job.

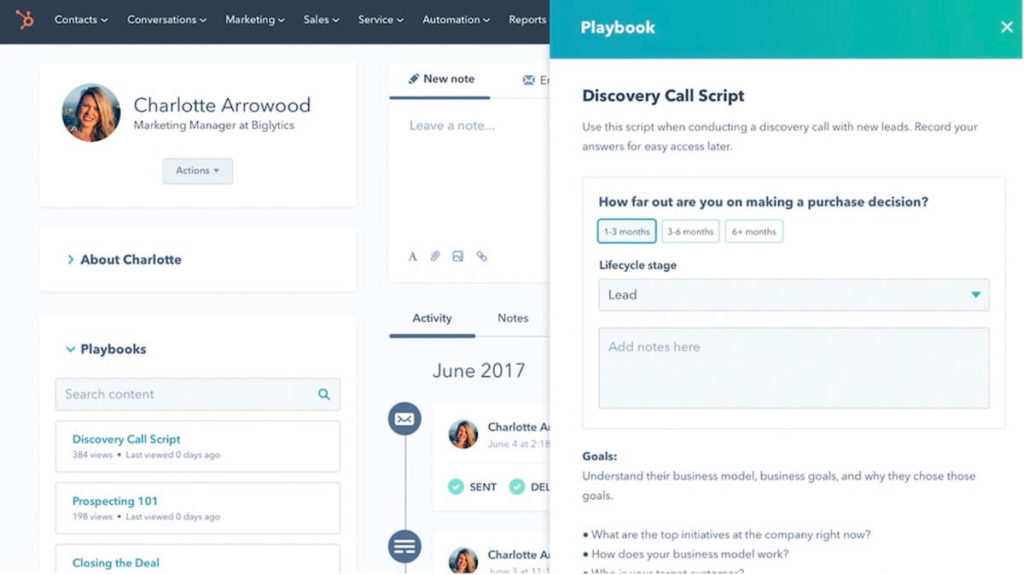

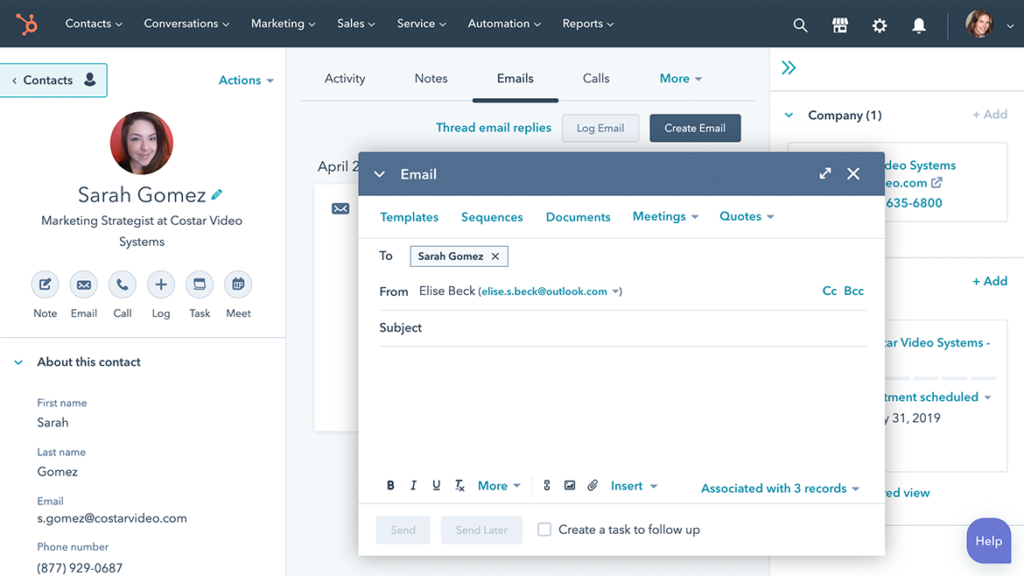

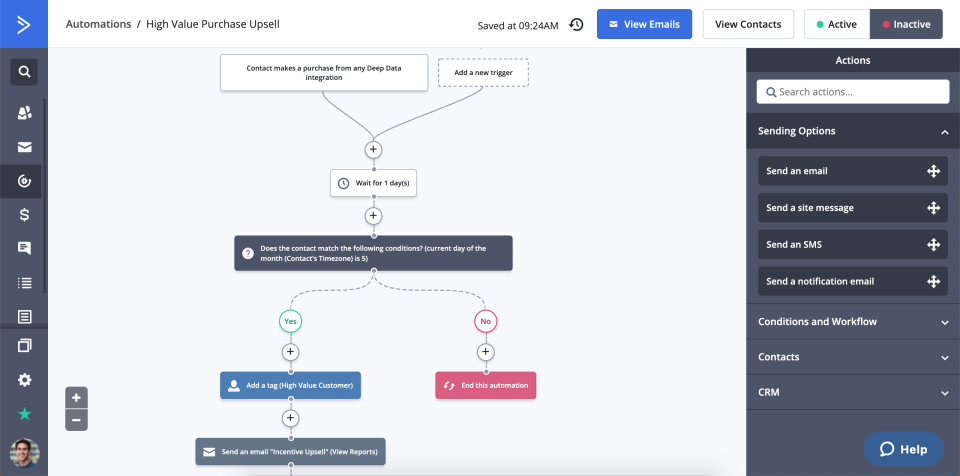

Marketing features

A CRM with marketing automation is a must to streamline and track your marketing efforts.

This is especially true once your business achieves substantial growth and manually tracking marketing efforts becomes overwhelming.

Key CRM marketing features include:

- Email campaigns.

- Embedded web forms.

- Marketing software integrations.

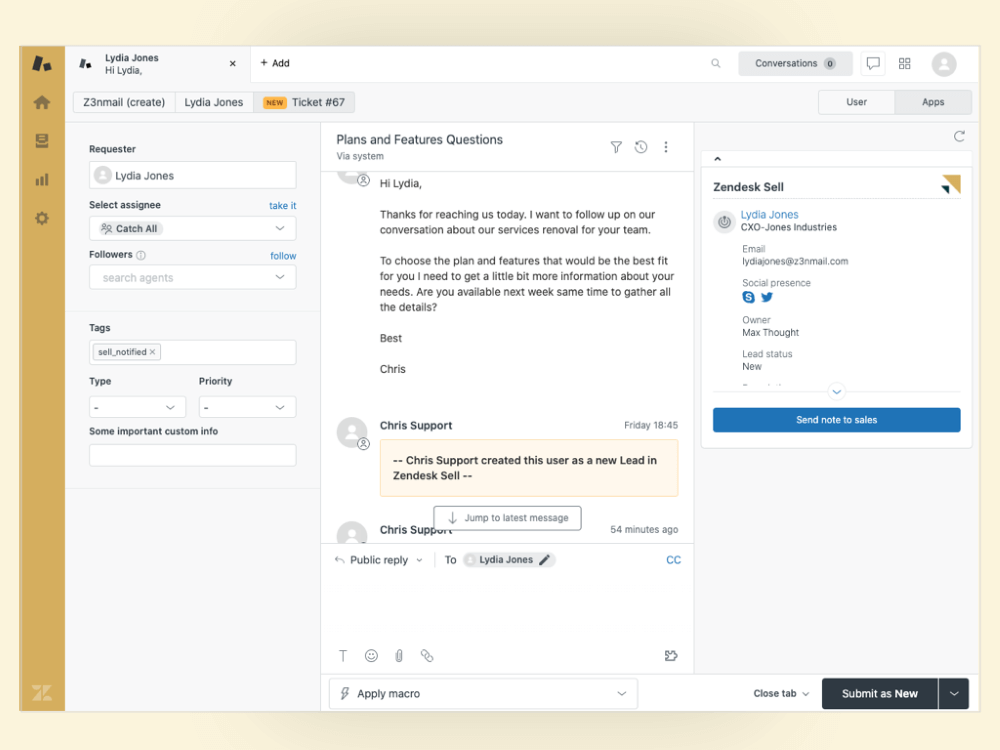

Customer service features

Your customers keep your business afloat, so customer service should be your top priority.

A CRM improves your customer service with features such as:

- Central database to store customer information.

- Automatic follow-ups.

- Easy payment processing.

What’s more, a CRM that goes above and beyond has additional features to bring every aspect of your business to a new level.

Advanced features of custom CRM

Basic CRM features may be enough to get you started, but as your business grows, so should your software.

Here are some advanced features to consider when figuring out how to build a CRM system.

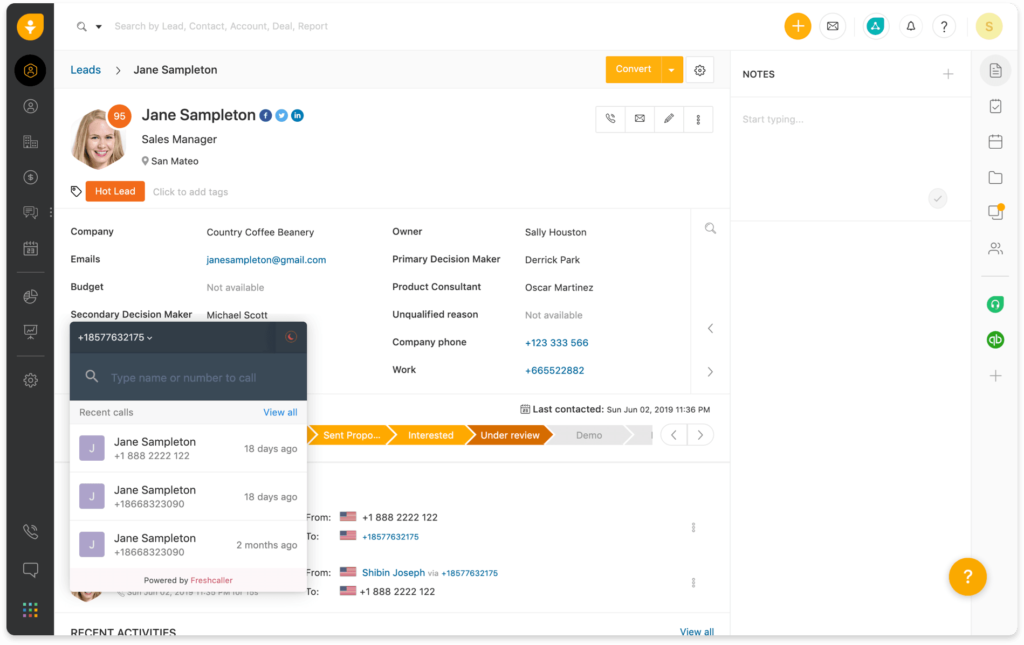

Distinct lead management

To stay organized, keep your paying customers and your potential customers separate in your system.

Unfortunately, not all CRM software allows for this.

Keep lead management in mind when deciding how to build a CRM system for your business. Your leads represent the future potential of your business, so you need to nurture them with particular attention to detail.

A CRM with good contact management lets you focus on your leads and give them each the attention they need to make it through the sales pipeline.

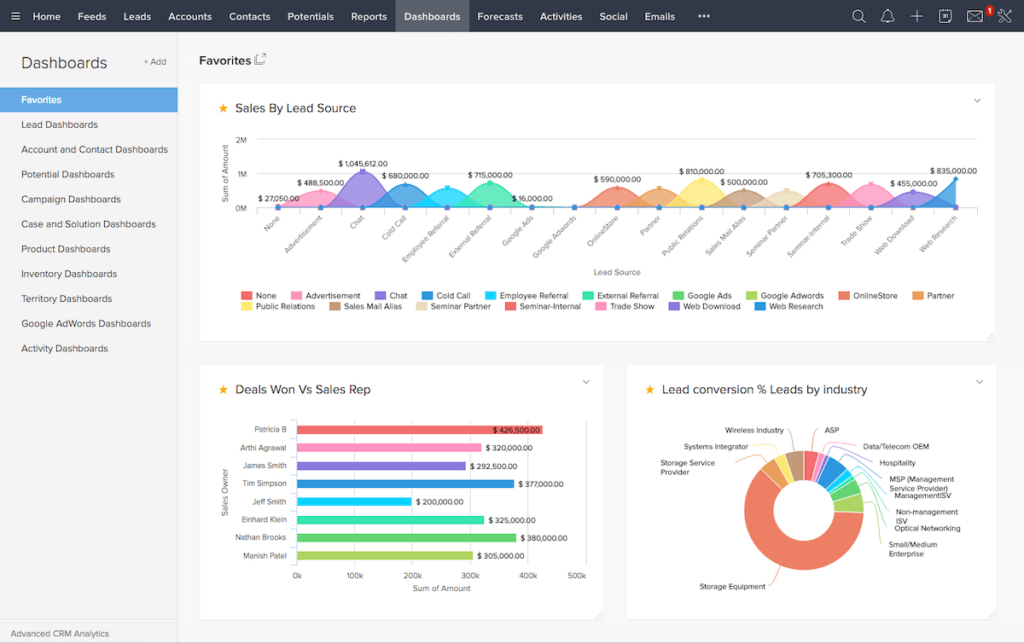

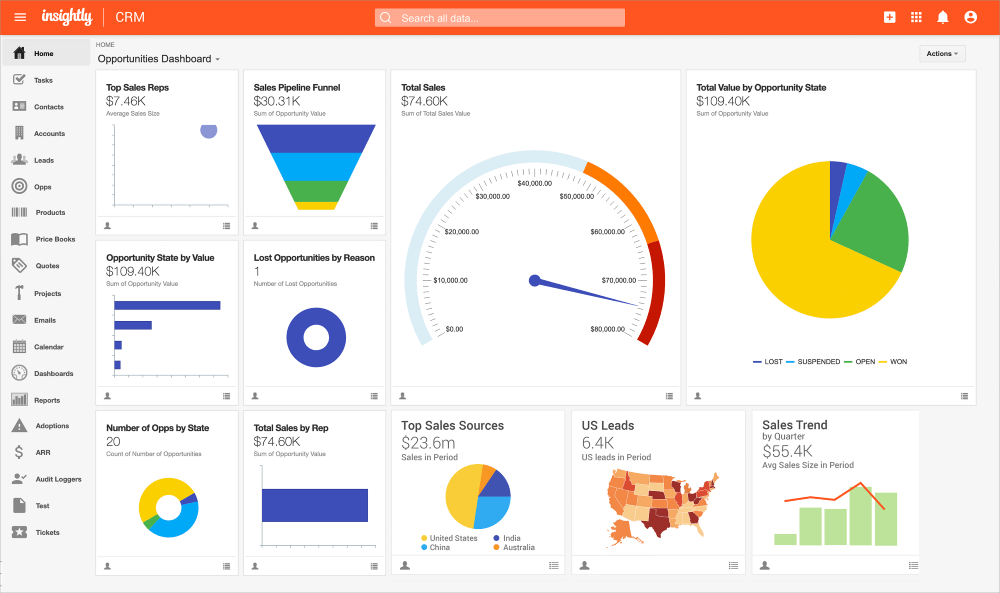

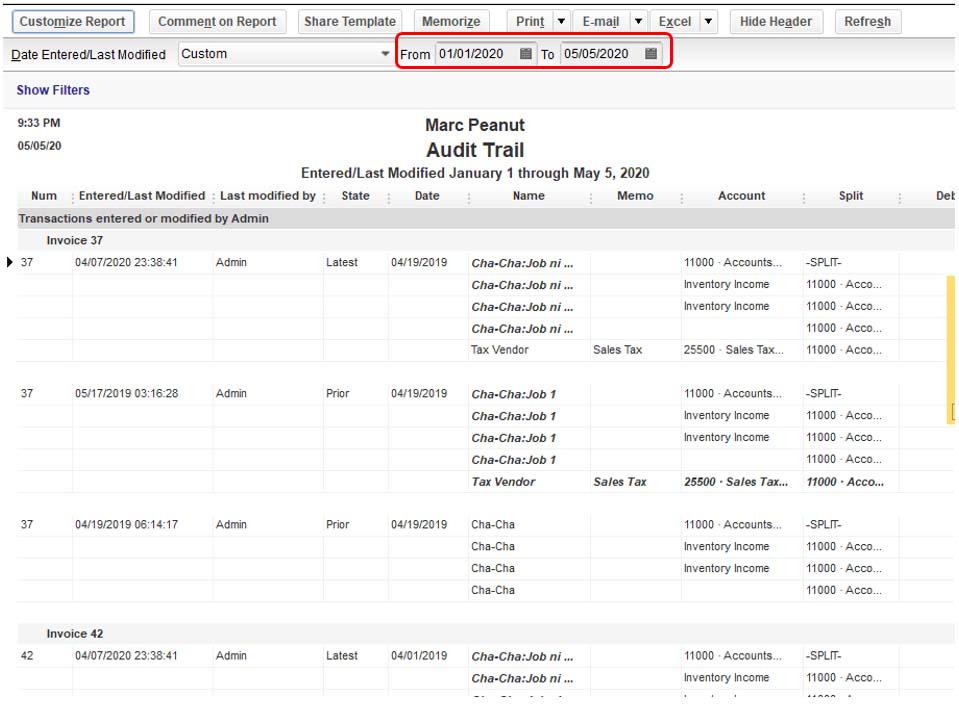

Detailed reporting and analytics

You must keep track of the past and present to move your business forward. This is best done through custom reporting.

Reports let you know how your business is doing. They show you what’s working well and point out weaknesses you may not have noticed otherwise.

Custom reporting allows you to identify those weaknesses fast and act even quicker to fix them.

Online customer portal

Another advanced feature to note when considering how to build a CRM system is an online customer portal.

As friendly as your customers may be, chances are that they don’t want to pick up the phone or send an email every time they engage with your business.

This is why self-service options are so popular across businesses.

An online portal empowers your customers and boosts your customer service. It allows your customer to:

- Submit inquiries.

- Approve documents.

- Pay and retrieve invoices.

The best part is that this means less manual work for your team! And that’s only one of several benefits of CRM software.

Benefits of CRM solutions

Integrating a CRM system carries several benefits for your teams and overall business.

For example, sales reps gain a comprehensive view of your customers to deliver a better customer experience. Accounting and invoicing are also improved if your CRM carries advanced features.

Here are a few other top benefits of CRM software:

- Gain access to a variety of tools to organize your processes.

- Save time on admin work that you can reinvest into growing your business.

- Strengthen your processes to boost productivity.

- Increase customer satisfaction and customer retention.

A CRM solution dramatically impacts your business, but a custom CRM system can grow your business into what you’ve always dreamed of.

Why creating a custom CRM system is worth it

Ready-made CRM software is convenient and easy if you’re looking for a solution to improve your current customer relationship management.

But if you’re looking for a CRM that blends seamlessly into your business processes, you may have trouble using one-size-fits-all software.

One solution is learning how to build a CRM system that’s custom-tailored for your business. This helps prevent a lack of features or seemingly useless ones from getting in the way.

Doing so ensures you know exactly how your software works from the get-go, so you don’t have to dedicate hours to learning a new system.

That said, you will have to dedicate some time to building the system.

The benefits of building your own CRM may only be worth it if you have strong development skills and are invested in the project.

Cost of custom CRM development

Building a custom CRM is more than a weekend DIY project.

While a custom CRM saves you time and money down the line, building the system requires a significant commitment that can deprioritize revenue-generating activities for a while.

The best way to approach building a CRM is with the help of an expert.

A variety of development companies specialize in helping small businesses build custom software, such as CRMs, or that take on the job entirely for you.

To demonstrate, let’s now look at how to build a CRM system with a developer.

How to build a CRM system with a developer

Here are six steps toward building a custom CRM system with a development partner.

1. The preoperational stage

The first step in how to build a CRM system – whether by yourself or with some help – is the preoperational stage.

The preoperational stage is a brainstorming session where you determine what exactly your business needs out of a CRM.

For this brainstorming session, you should involve everyone who will be using the CRM, including:

- Sales managers.

- Marketing directors.

- Customer support managers.

Your team members will have the best insights into the needs of your business and can contribute to a cross-departmental solution.

2. Choose a development company

While you can attempt to engage your internal development team in your CRM project, their expertise may be limited to your core business.

It’s a good idea to work with industry experts who can guide you when creating your custom CRM software.

Key things to verify when choosing a development partner are:

- Their portfolio.

- Industry experience.

- Previous client reviews.

3. Contact your potential development partner

Once you find a suitable developer, approach them to assess if they can execute your custom CRM software ideas.

Be prepared for your potential developer to come back to you with additional questions on how you want your custom solution designed.

Come up with your own set of detailed questions to ensure you’re both on the same page.

4. Keep an open mind

While you may think you’re approaching a developer with the perfect CRM system plan, they may suggest changes or improvements.

During this process, remember that there’s a reason why you chose to seek the help of a professional.

Keep an open mind with every iteration of the design your developers bring to you. While they don’t know your business as well as you do, they may have insights or ideas that might have escaped you.

5. Approve the final design

Make sure to include all of your company’s stakeholders in the final design’s approval.

This ensures that nothing is overlooked and allows you to address any problems before your developers get to work.

During this final approval stage, make sure to confirm:

- Development cost.

- Development time.

- Time frame for updates.

6. Roll out your new CRM system

Once your developer delivers your new CRM software, it’s time for deployment. Take the opportunity to test your new custom software before fully implementing it.

Get your staff involved with testing so that all areas of your business are covered. Also, let your developer know about any needed changes or bugs to fix.

Finally, establish plans for future support needs should you run into trouble later on. Maintaining a good relationship with your development partner is the best way to ensure that you always have the support you need.

After reading these steps, you may decide that:

- Figuring out how to build a CRM is too much of a time commitment.

- Hiring a developer is too costly.

But if that’s the case, this isn’t the end of the road.

Alternatives to learning how to build a CRM system

Should you choose not to build your own CRM, it doesn’t mean you have to settle for a ready-made solution.

There are a couple of alternatives to learning how to build a CRM that will still provide personalized results.

First, you can use a third-party app such as Zapier to connect the tools you already use.

This particular integration connects your apps and moves information between them based on the rules you set, empowering you to devise your automated CRM system.

However, figuring out which apps to connect and different triggers can be a challenge, and you may not have all the features you need.

Instead of figuring out how to build a CRM from scratch, opt for a customizable CRM.

Before you build a CRM – Consider Method

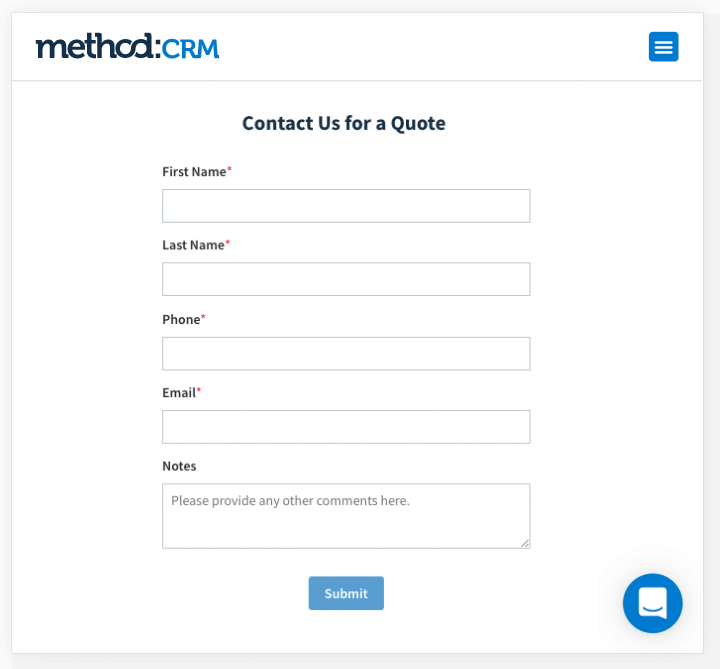

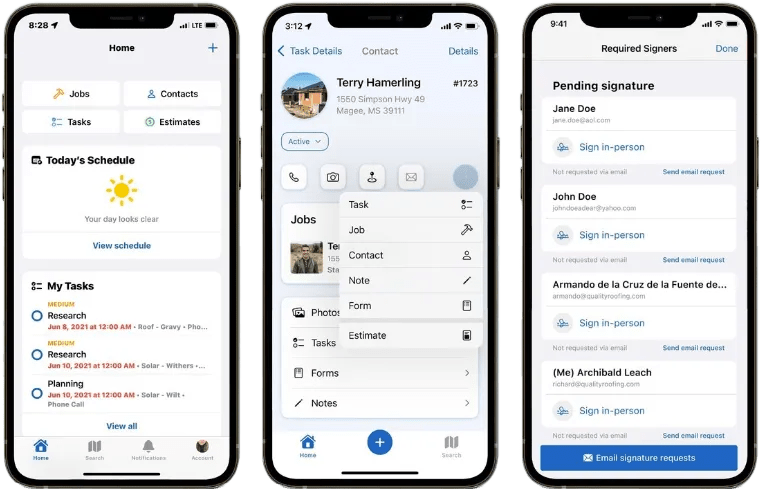

Method CRM is the ultimate compromise between ready-made CRM systems, learning how to build a CRM system, and hiring a developer for a custom solution.

Method is a no-code platform, meaning you don’t need a developer to personalize the system. This versatility makes it the perfect custom CRM system for small business budgets.

If you still need guidance or want someone to take over and execute your vision, Method’s customization experts are here to help.

With unlimited customization, the possibilities are endless.

Create custom reports to analyze data in the way that makes the most sense for your business and better informs your decisions.

Method also allows you to customize:

- Online customer portals.

- Transaction templates.

- Web to lead forms.

Its two-way sync keeps data flowing between your accounting software and your CRM. So what you see in Method will also appear in QuickBooks or Xero.

Some of Method’s native integrations include:

- Outlook.

- Gmail.

- Google Calendar.

- Paypal.

You can also use Zapier to integrate other third-party tools into Method CRM.

Wrap up: Building a custom CRM system is an investment

There are endless software options, but nothing beats a custom CRM solution built for your every business move.

Even if this article didn’t inspire you to figure out how to build a CRM system, you hopefully discovered alternatives that will strengthen your business processes and boost your success.

How to build a CRM system FAQs

How do you build a good CRM?

To build a good CRM, you must first understand your business needs, work out current weaknesses, and determine the features that would help you overcome those weaknesses. Then, decide whether to hire a developer or build your own CRM.

How hard is it to build a CRM?

Learning how to build a CRM system is challenging if you don’t have a developer background. It’s a considerable time investment, which could affect your business’ profits. Because of this, opting for a customizable CRM that lets you personalize the solution without starting from scratch may be the best call.

What are the 4 pillars of CRM?

The four pillars of CRM are people (your team), strategy (to promote growth), processes, and technology.

Bring your perfect CRM to life with your free trial of Method CRM!

Image credit: Andrea Piacquadio via Pexels