A work order in manufacturing outlines the steps in the production process. Some are simple, some more complex. But all work orders contain key information necessary for them to be effective.

There are various work orders, each with its specific purpose. A manufacturing work order, for instance, typically involves maintenance, inspection, and emergency processes.

Keep reading to learn what a work order in manufacturing entails, its benefits, and how to create the perfect manufacturing order form.

What is a work order in manufacturing?

A work order in manufacturing is a type of work order that documents the manufacturing process.

It includes all the necessary information to complete the work, such as material requirements, labor, and machine time.

The work order should also list any special instructions for the work performed.

For instance, if a particular part of the process requires extra care or additional steps, you should note that on the manufacturing order form.

Work order vs. work request

It’s important to note that a work order is not the same as a work request.

A work request is simply a document that requests work to be done. It does not provide any instructions on how to do the job.

On the other hand, a work order provides specific instructions on what needs done and any necessary information to complete the work.

Types of work orders

As mentioned above, there are various manufacturing work orders, each with its specific purpose. Take a look at some of the most important types.

General work order

A general work order in manufacturing documents all the work that needs to be done in a factory.

It should also list any special instructions for the work performed, such as material requirements, labor, and machine time.

Preventive maintenance work order

A preventive maintenance work order documents the work that needs to be done to prevent equipment failure. Potential issues are diagnosed during routine maintenance inspections.

This work order is important because it can help avoid costly downtime and repairs.

Inspection work order

An inspection work order is a work order that includes what needs to be done to inspect equipment. Inspection entails identifying problems to correct at a later time.

This type of work order is crucial because it can help identify problems before they escalate.

Emergency work order

An emergency work order defines the work that needs to be done in an emergency.

For instance, if a machine breaks down and needs immediate repair, you would create an emergency work order.

Corrective maintenance work orders

A corrective maintenance work order is brought on by unplanned equipment failure.

This work order is not typically created for issues that can be quickly fixed or onsite repairs. The main difference between preventive and corrective maintenance is that the latter is scheduled and planned for later action.

What should be in a work order?

A work order in manufacturing tells the workers in a factory what to make and how to make it.

The work order lists the needed materials and the steps to follow. For example, a work order for a table will list the type of wood, the measurements, and how to put the table together.

It also helps to track the progress of the manufacturing process. The work order will list the start and finish times for each step, and you can use it to track the entire project’s progress.

Ultimately, a manufacturing work order ensures that products are made correctly and efficiently.

Benefits of using work order management software

Now, look at the main benefits of using work order management software in manufacturing.

1. Improve communication

The most important benefit is that the right software improves communication between workers and managers.

With software, you can store all the information about a project in one place.

This means that everyone involved in the project can easily access the same information to avoid misunderstandings and mistakes.

2. Maximize efficiency

Work order management software can also help to increase efficiency through workflow automation.

For example, if a work order is changed, the software can automatically update the information for all workers working on the project. This helps prevent delays and errors.

3. Track progress

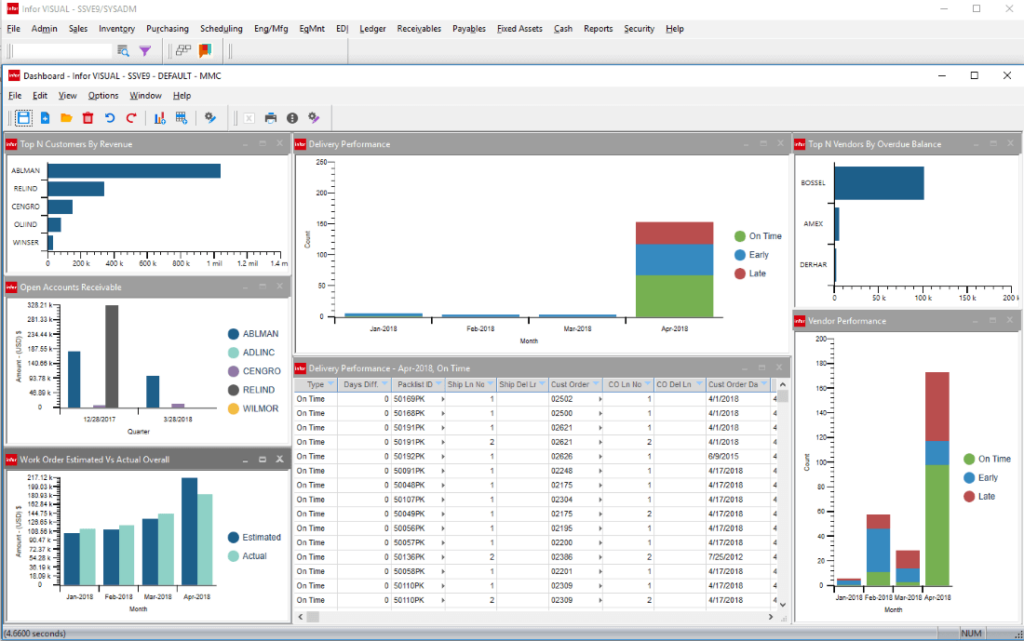

Work order management software tracks the progress of your project.

You can use this information to identify bottlenecks and problems. You can also use it to create reports that you can share with clients and shareholders.

4. Improve quality

Another significant benefit is that work order management software betters your product quality. Here’s how.

If there are issues with a work order, you can use the software to identify the problem and correct it.

This helps to ensure that products are made correctly and meet your standards. It also minimizes the chance of expensive product recalls.

5. Reduce costs

Finally, work order management software reduces costs.

Work order management software lets you save time and money by improving communication and maximizing efficiency with automation.

How to handle work orders in manufacturing

Now that you know the benefits of work order management software, read up on handling work orders in manufacturing.

Tracking the expenses

There are a few different ways to track expenses in a work order.

One way is to create a separate line item for each expense. This is helpful if you have many expenses to keep track of.

Another way is to lump your expenses together into one line item. This is ideal if you have a few different expenses or want to keep track of your overall manufacturing costs.

Regardless of your chosen method, it’s essential to be as accurate as possible when tracking your work order expenses.

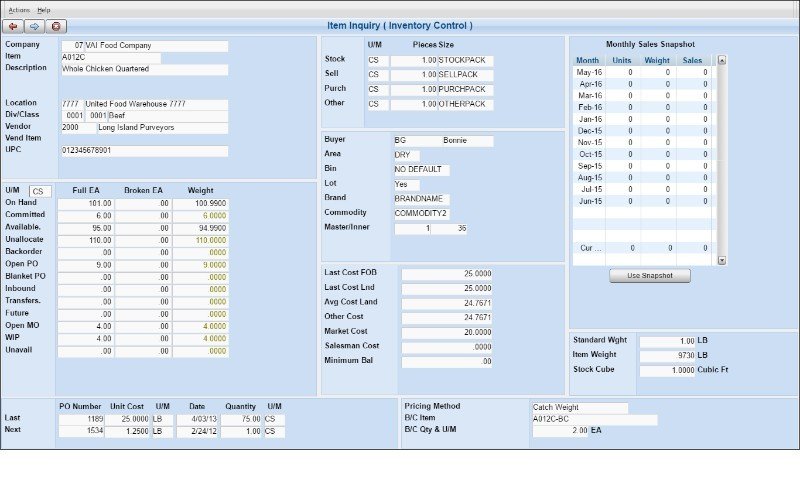

Direct materials

Once you’ve determined the direct materials for a work order, you need to track how much of each material is used. This can be done by weight, volume, or some other unit of measurement.

Pro-tip: Ensure you’re as accurate as possible when tracking direct materials.

Otherwise, you risk using too much of a material (which drives up costs) or not using enough (which can cause production delays).

How to create the perfect work order

To ensure that your manufacturing order form is created correctly, there are three steps that you need to follow:

1. Inputting the data — Add data into the work order management software such as the materials needed, steps to be followed, and the start and finish times for each step.

2. Tracking progress — One way you can do this is by using the work order management software to create reports. These reports can then be shared with clients and shareholders if needed.

3. Updating information — Add any changes that are made to the project including changes to the work order, new steps that need to be added, or anything else that might affect the project.

Manufacturing work order template

When creating a manufacturing order form template, you have a few options for what to include.

Whether you build your template on Excel or Google Sheets, you always save time in the long run.

If you want to go beyond a spreadsheet’s limitations, consider a manufacturing management software.

Take Method CRM for example. You can empower your team with the workflow automation they need to grow your manufacturing business.

From generating new leads to processing orders and managing customers, Method CRMl syncS all your data instantly with QuickBooks or Xero.

Learn more about Method CRM’s capabilities with this video.

Answering the question, “What is a work order in manufacturing?” helps you outline the steps in the production process. Some are simple, some more complex. But all work orders contain key information necessary for them to be effective.

There are various work orders, each with its specific purpose. A manufacturing work order, for instance, typically involves maintenance, inspection, and emergency processes.

Keep reading to learn:

- What is a work order in manufacturing?

- The benefits of work orders.

- How to create the perfect manufacturing order form.

Let’s jump in!

What is a work order in manufacturing?

Put simply, a work order in manufacturing is a type of work order that specifically documents the manufacturing process.

It includes all the necessary information to complete the work, such as:

- Material requirements.

- Labor.

- Machine time.

A work order should also list any special instructions for the work performed.

For instance, if a particular part of the process requires extra care or additional steps, you should note that on the manufacturing order form.

Work order vs. work request

Note that what is a work order in manufacturing is not the same as a work request. A work request is simply a document that requests work for a project. It does not provide any instructions on how to do the job.

On the other hand, a work order provides specific instructions on what needs to be done and any necessary information to complete the work.

Types of work orders

As mentioned above, there are various manufacturing work orders, each with its specific purpose. Take a look at some of the most important types so you can better answer, “What is a work order in manufacturing?” and learn how it’s an asset to your business.

General work order

A general work order in manufacturing documents all the work that you need to do in a factory.

It should also list any special instructions for the work performed, including material requirements, labor, and machine time.

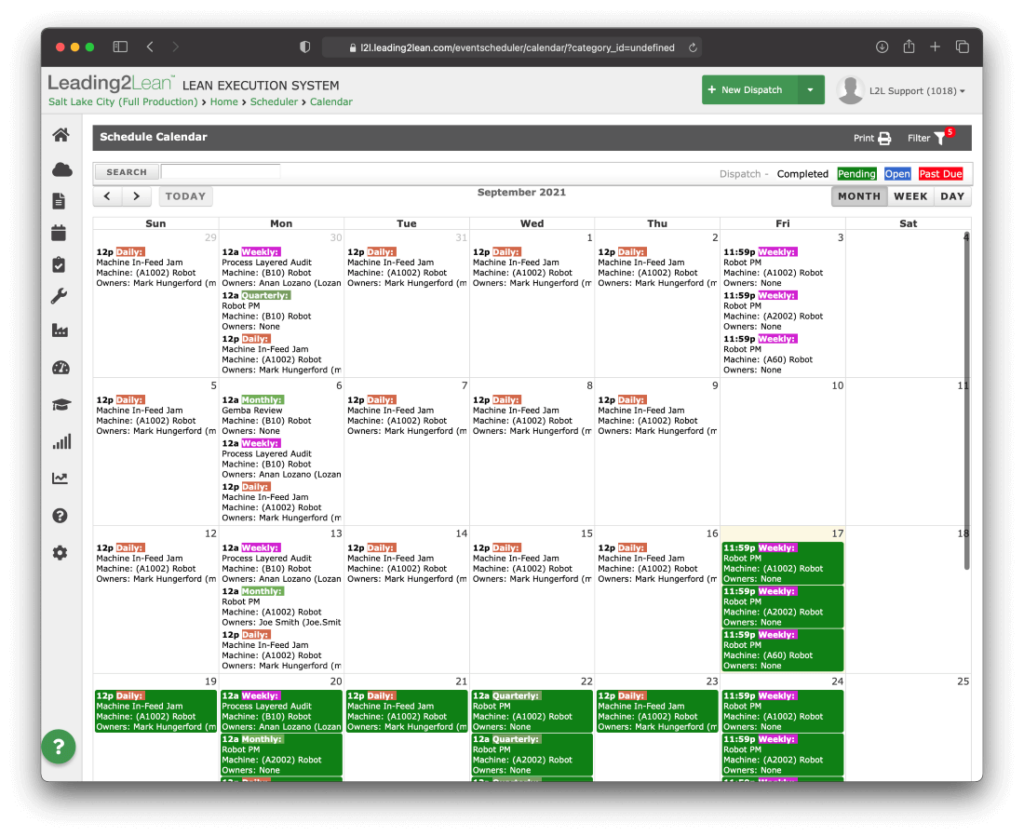

Preventive maintenance work order

A preventive maintenance work order documents the work required to prevent equipment failure. You can diagnose potential issues during routine maintenance inspections.

This work order is important because it helps avoid costly downtime and repairs.

Inspection work order

An inspection work order is a work order that includes all the necessary steps to inspect equipment. Inspection entails identifying problems to correct at a later time.

This type of work order is crucial because it helps identify problems before they escalate.

Emergency work order

An emergency work order defines work that’s needed in an emergency situation.

For instance, if a machine breaks down and needs immediate repair, you would create an emergency work order.

Corrective maintenance work orders

A corrective maintenance work order is brought on by unplanned equipment failure.

You don’t typically create this kind of work order for issues that are quickly fixable or for onsite repairs. The main difference between preventive and corrective maintenance is that corrective maintenance involves a reaction to a problem, while preventive measures involve taking action to stop those problems from occurring in the first place.

What should be in a work order?

A work order in manufacturing tells the workers in a factory what to make and how to make it.

It lists the needed materials and the steps to follow. For example, a work order for a table would list:

- The type of wood.

- The measurements.

- How to put the table together.

It also helps to monitor the progress of the manufacturing process. The work order lists the start and finish times for each step, and you can use that information to track the entire project’s progress.

Ultimately, a manufacturing work order ensures that goods are made correctly and efficiently.

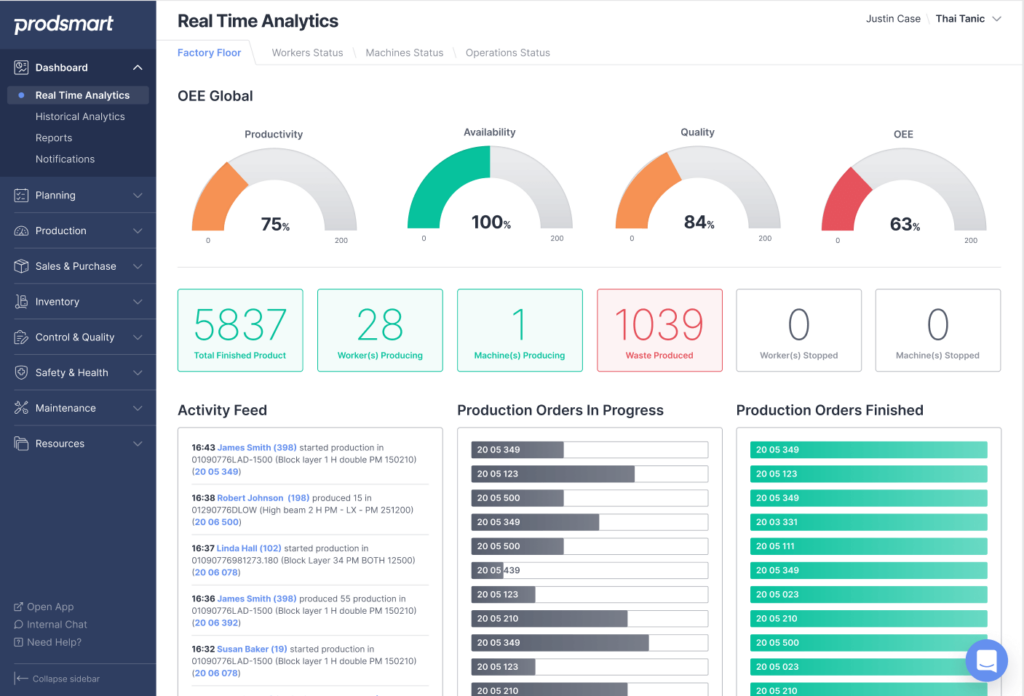

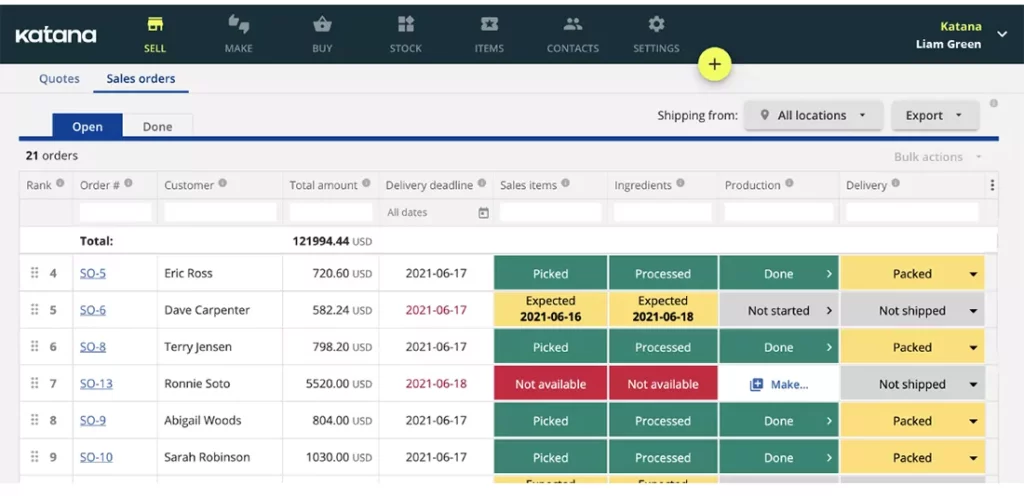

What is work order management software?

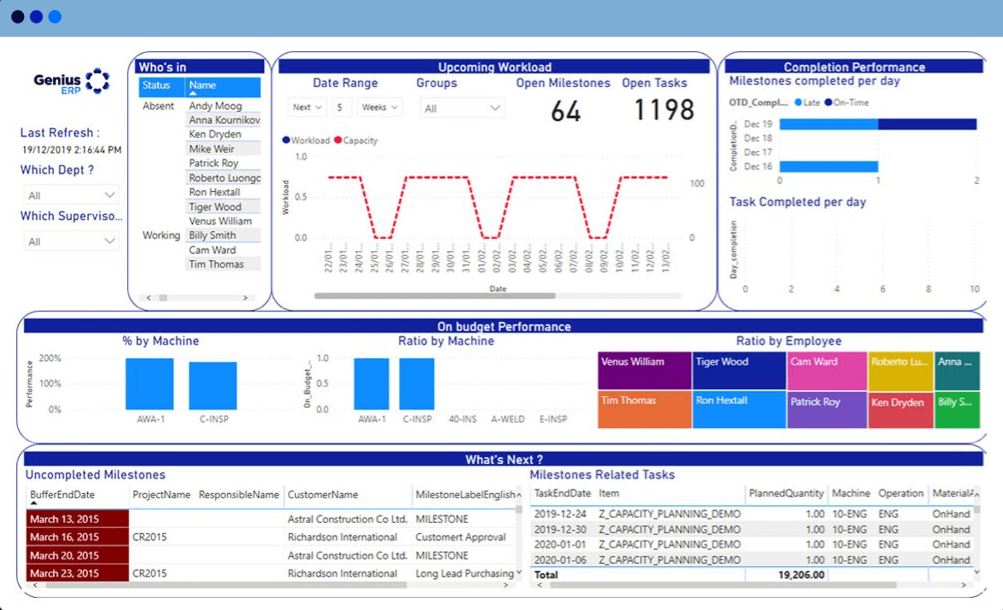

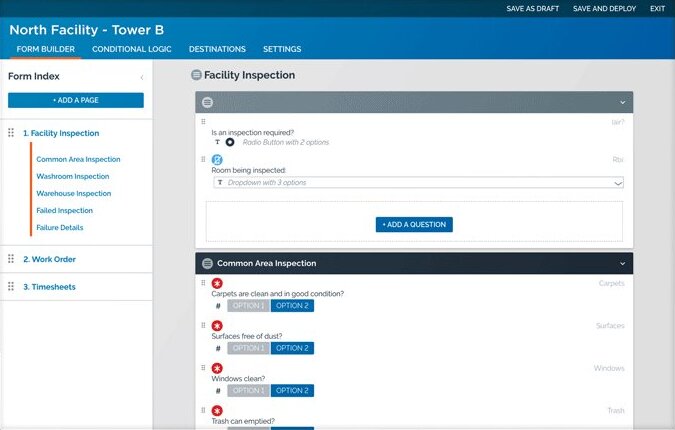

Work order management software is a digital tool that helps you simplify and organize your manufacturing operations. This software helps you assign tasks and track your progress across all parts of the manufacturing process to give you total control of the details.

Work order management software helps you monitor:

- Shop floor organization.

- How to allocate resources across machines and departments.

- Labor requirements and cost estimates of equipment and tools.

- Traceability of compliance and documentation,

- Team performance, which helps you promote accountability for each supervisor.

- Your production schedule, letting you review, approve, and execute each step.

- Revision control to prevent delays and wasted materials.

Having a good understanding of what is a work order in manufacturing software helps you prioritize your workflow management and update your systems for continuous improvement.

Benefits of using work order management software

Now, let’s look at the main benefits of using work order management software in manufacturing.

1. Improve communication

The most important benefit is that the right software improves communication between workers and managers — and between you and your customers.

With software, you store all the information about a project in one place.

This means that everyone involved in the project can easily access the same information to avoid misunderstandings and mistakes.

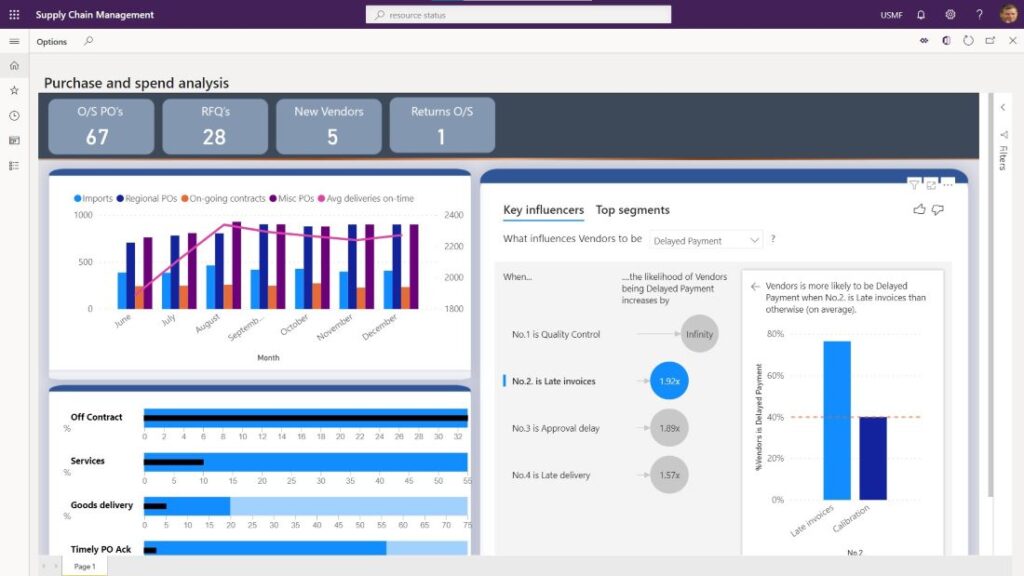

2. Maximize efficiency

Work order management software also increases efficiency through workflow automation.

For example, if someone changes a work order, the software will automatically update the information for all workers on the project. As a result, you prevent delays and errors.

3. Track progress

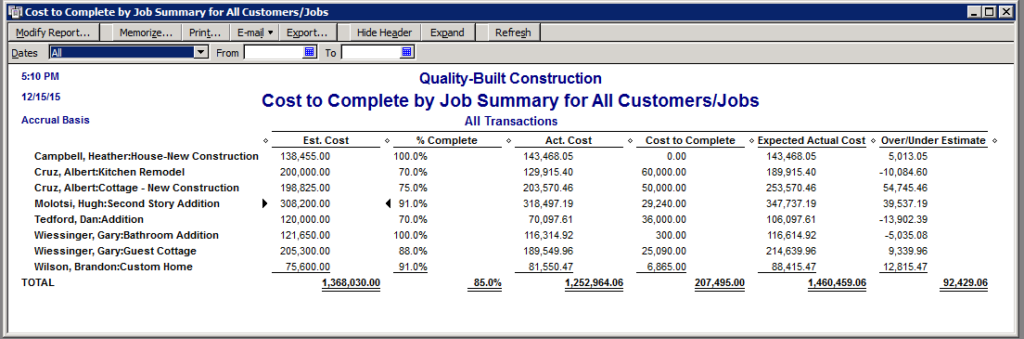

Work order management software tracks the progress of every project from start to finish. The more data you collect on job progress, the more productive your team will be down the road.

You can use this information to identify bottlenecks and problems. You can also use it to create reports to share with clients and stakeholders.

4. Improve quality

Another significant benefit is that work order management software betters your product quality. Here’s how.

If there are issues with a work order, you can use your software to identify the problem and correct it.

This helps you ensure the proper assembly of products to meet your standards. It also minimizes the chance of expensive product recalls. A work order paves space to communicate about specific jobs with your customers, letting you can shape your product more towards their wants and needs.

5. Reduce costs

Finally, work order management software reduces costs.

The platform lets you save time and money by improving communication and maximizing efficiency with automation.

How to handle work orders in manufacturing

Now that you know the benefits of work order management software, read up on handling work orders in manufacturing.

Tracking expenses

There are a few different ways to track expenses in a work order.

One way is to create a separate line item for each expense. This is helpful if you have many expenses to keep track of.

Another way is to lump your expenses together into one line item. This is ideal if you only have a few different expenses, or want a cost analysis of your overall manufacturing costs.

Regardless of your chosen method, accuracy is essential when tracking your work order expenses.

Direct materials

You also need to monitor and account for all the direct materials you’ll need to complete a job. Analyze the scope of the job and air on the side of caution if you’re worried about underordering.

Once you’ve determined the direct materials for a work order, you need to track your resource allocation. This can be done by weight, volume, or some other unit of measurement.Otherwise, you risk using too much of a material (which drives up costs) or not using enough (which can cause production delays).

How to create the perfect work order

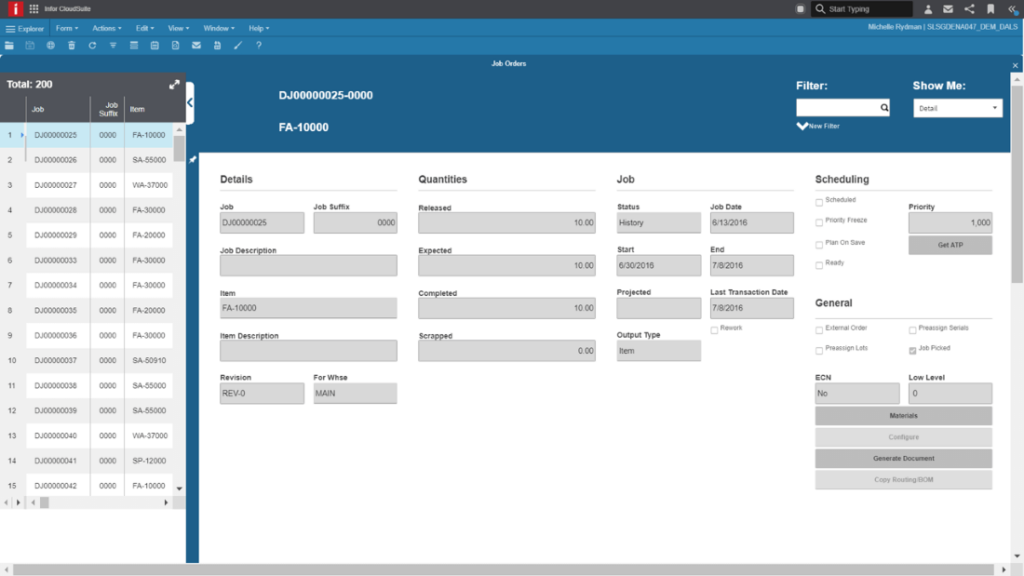

To ensure that you’ve created your manufacturing order form correctly, there are three steps you need to follow:

1. Input the data — Add data into your work order management software, such as the materials needed, steps to follow, and the start and finish times for each step.

2. Track progress — One way you can do this is by using your work order management software to create reports. You can then share these reports with customers and stakeholders if needed.

3. Update information — Add in any changes that are made to the project, including:

- Adjustments to the work order.

- New steps that you need to add.

- Anything else that might affect the project.

Manufacturing work order template

Now that you have a better understanding of what is a work order in manufacturing, you’ll want to make your own work order template.

Whether you build your template on Excel or Google Sheets, you always save time in the long run.

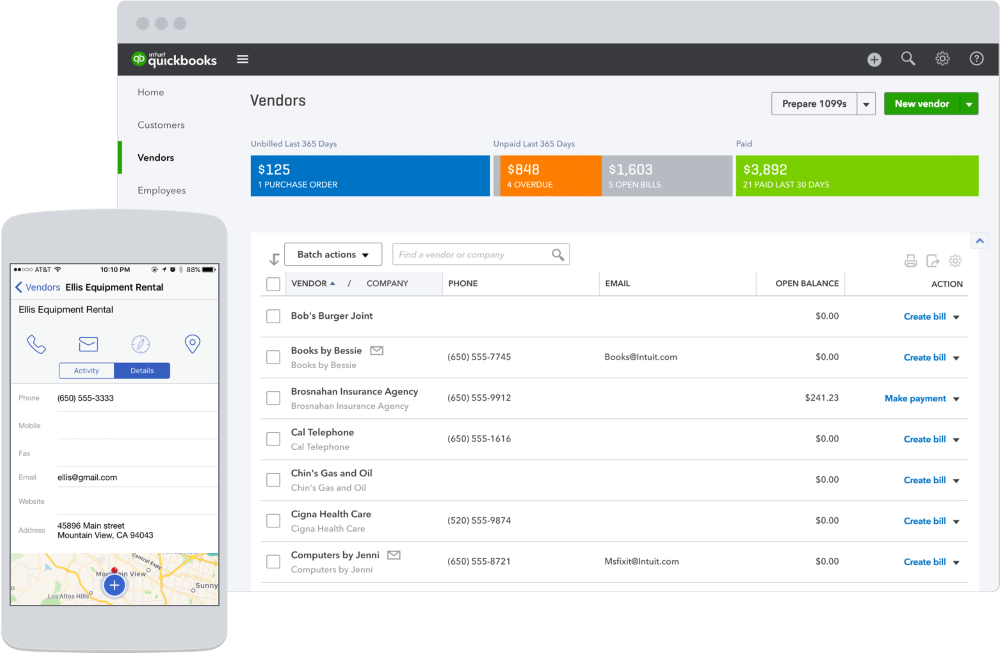

But, if you want to go beyond a spreadsheet’s limitations, consider using manufacturing management software.

Take Method, for example. You can empower your team members with the workflow automation they need to grow your manufacturing business.

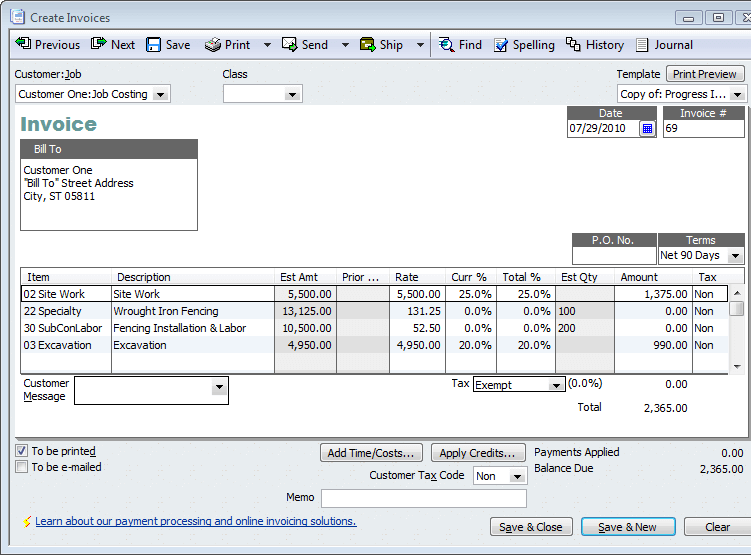

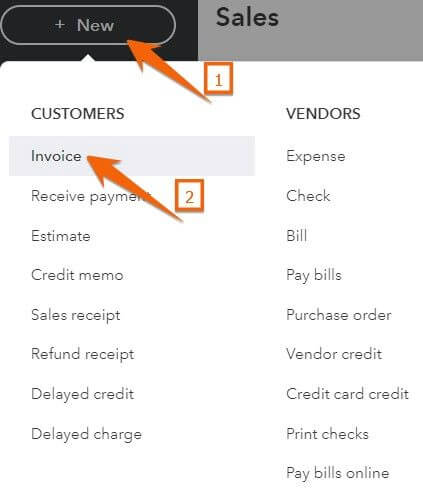

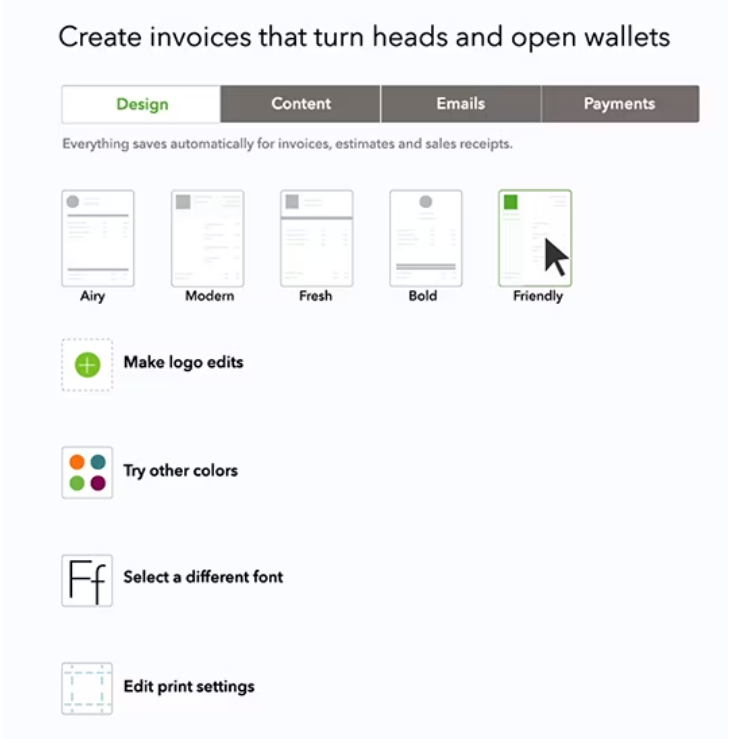

From generating new leads to processing orders and managing customers, Method syncs all your data instantly with its seamless QuickBooks or Xero integration. This makes it easy to:

- Track inventory records.

- Automate invoice creation.

- Centralize your finances in a single place.

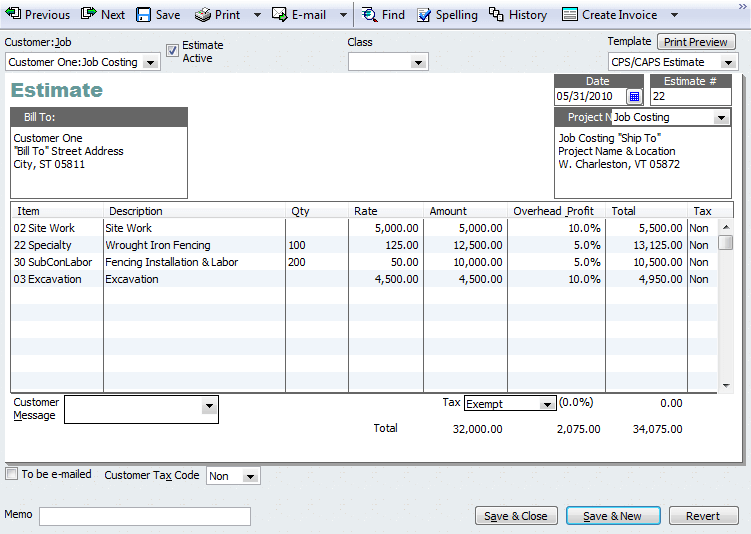

You can even create a work order directly in QuickBooks.Learn more about what services Method offers you in this video.

Future trends in work order management

The future of work order management hinges on an increasing reliance on software. This is because work order management software has many advantages that manufacturers rely on to improve production time and organization.

Let’s take a closer look at these advantages!

Automation and artificial intelligence

Artificial intelligence (AI) is becoming an increasingly popular choice for manufacturing software systems, as they use machine learning to validate decision-making specifically related to your business.

As a result, you benefit from:

- Accurate reporting.

- Increased productivity.

- Reduced manufacturing downtime.

Predictive maintenance

Predictive maintenance uses sensors and software to anticipate when equipment will require maintenance and prevent unexpected breakdowns. This is a proactive approach to keep operations running smoothly and reduce maintenance costs.

Augmented reality (AR) and virtual reality (VR)

Manufacturing businesses are now using AR and VR technology as a new way to:

- Train staff.

- Identify potential problems.

- Present real-time information on equipment performance.

These technologies help your workers visualize tasks and perform them more efficiently and safely.

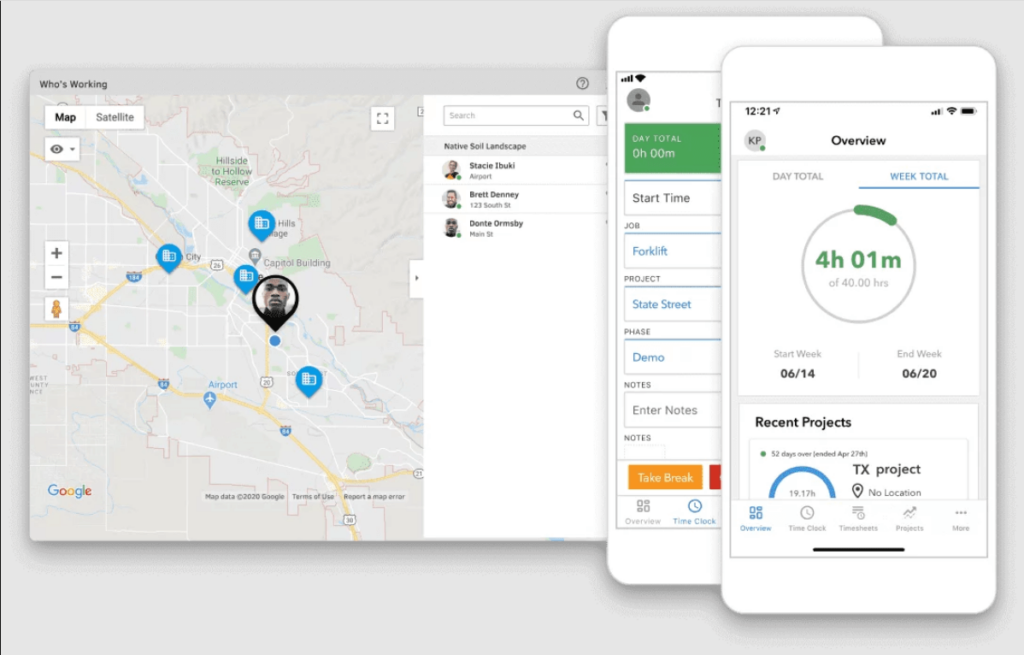

Mobile work order management

What is a work order in manufacturing when it comes to mobile management? This technology enables real-time access to work orders while you’re on the go to make it easy for collaboration between teams.

This mobility also improves response times and the flexibility of your operations.

Cloud-based work order management systems

A cloud-based work order management system is available online, so you can access it remotely from anywhere with an internet connection. Work order management software that uses cloud technology often includes benefits like real-time data sharing.

Key takeaways

Now that you’ve answered, “What is a work order in manufacturing?” you’re ready to track jobs more effectively and earn more business.

A work order in manufacturing is essential to ensuring process efficiency. The good news is that there are a few different ways to go about tracking sales and expenses.

All in all, having a manufacturing software solution like Method in place saves you time and money and helps you optimize your business all around.

Manufacturing work order FAQs

What is the difference between BOM and work order?

A bill of materials (BOM) is a highly detailed list of items needed to manufacture a product. In contrast, a work order includes detailed instructions for making the product. A work order references the BOM to manufacture a specific number of products, while also meeting quality standards and laying out job details.

What is the difference between a manufacturing order and a work order?

The difference between a manufacturing order and a work order is that a manufacturing order gives the overall direction for how a product is made. It usually includes the general steps and processes involved. On the other hand, a work order includes a more specific description of each task involved in the manufacturing process.

Knowing what is a work order in manufacturing as opposed to a manufacturing order helps you gain a better understanding of the work processes involved and how to organize them.

How do you create a manufacturing work order?

To create a manufacturing work order, you need to manually write it out or use a designated software solution.

A manufacturing work order defines:

- The work to be carried out.

- The necessary raw materials.

- Who will be carrying out the work.

Once you’ve established all three, it’s best to leverage work order management software to quickly:

- Issue work orders.

- Track progress.

- Update information as needed.

What is work order process?

The work order process is a series of steps to complete a work order. This generally includes:

- Inputting data.

- Tracking progress.

- Updating information.

Why do companies use work orders?

Companies use work orders to track the progress of a project and ensure that all work is completed in a timely manner. Knowing what is a work order in manufacturing and how to use one will help keep your team efficient and organized.Are you ready to organize your manufacturing operations and improve productivity?

Perfect your work orders with a free trial of Method CRM!

Photo credit: Kateryna Babaieva via Pexels