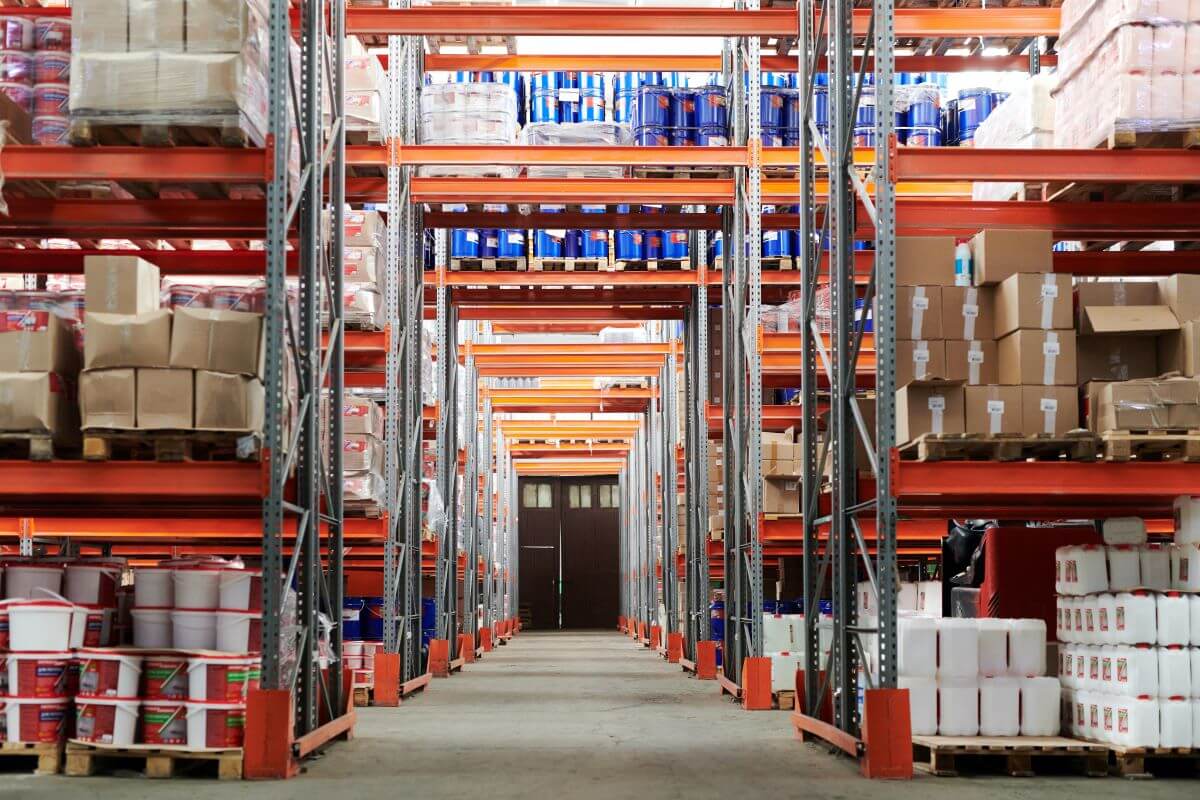

Manual warehouse management is a tedious process that consumes valuable time and may lead to costly mistakes.

Fortunately, warehouse management systems can assist you in stock management, inventory processing, and other crucial warehouse processes.

With QuickBooks Warehousing Manager, you can process orders and prepare them for shipping without hassle.

Read on to learn more about warehouse management software and why QuickBooks Warehousing Manager is one of the best choices for your business.

What is a warehouse management system?

A warehouse management system (WMS) is software that assists physical and e-commerce businesses in managing and controlling warehouse processes.

A good warehouse management system can track and monitor goods and materials from when they arrive at your warehouse to when they’re shipped off to customers.

Modern warehouse management systems usually have a set of standard primary features, which include:

- Goods receiving.

- Inventory management.

- Picking and packing.

- Order fulfillment and management.

- Warehousing analytics.

Why you need a warehouse management software

As customer demand for faster order fulfillment and shipments increases, so does the importance of warehouse management software in business operations.

If you’re still on the fence about implementing warehouse management software in your company, consider these benefits:

- Improve inventory management: Your warehouse management software works with inventory management software to track which products are in stock, show where they are, and even send notifications when stock is running low so you can order more.

- Deliver products faster: Today’s customers expect your product to arrive at their doors in one or two business days. Implementing a WMS can considerably shorten the picking and packing process, ensuring your goods are ready for shipping shortly after the customer submits an order.

- Track stock in real-time: WMS eliminates discrepancies between your store listings and actual inventory, automatically updating them to ensure customers know what products are still available.

- Prevent manual error: A WMS can automate some repetitive warehouse and supply chain management tasks, saving valuable time and minimizing mistakes. In addition to reducing errors, your employees can concentrate on more complex tasks that require a human touch.

Types of warehouse management systems

Before committing to a warehouse management system, you should know what types are available.

Below are three types of warehouse management systems popularly used today.

Standalone WMS

As the name implies, a standalone WMS only offers warehouse management features and nothing else. A standalone WMS usually comes as a physical server installed on-premise and connects to your distribution center’s hardware and network.

Standalone warehouse management systems are popular with smaller companies because they tend to be more affordable while still fulfilling their warehouse management software needs.

However, a standalone WMS tends to have a longer installation process because you have to schedule vendor visits.

ERP systems

Enterprise resource planning (ERP) software combines all your business processes in one dashboard for easier access. Software providers sell ERP by the module, which you can buy according to your business needs.

Most ERP system providers offer a warehousing module, which you can use just like any other WMS to improve your day-to-day inventory operations.

An ERP system also has the extra benefit of integrating all your business processes, so you don’t have to move data between divisions manually.

Cloud-based warehouse management software

Cloud-based WMS vendors use cloud technology to provide their services. Because everything happens on the Internet, you don’t have to install any hardware to use this software.

The lack of on-premise equipment means the installation process of cloud-based WMS is much quicker than traditional standalone WMS.

Additionally, vendors can update these cloud-based solutions anytime, in contrast, to on-premise WMS, which requires a vendor visit to update.

This means you can stay up to date with the latest warehouse management best practices and regulations without scheduling time-consuming vendor visits.

QuickBooks warehousing management system

In addition to accounting solutions for wholesalers and manufacturers, QuickBooks Online offers a warehouse management system to complement its inventory management features.

QuickBooks Warehouse Manager assists in order fulfillment by receiving inventory items from purchase orders.

QuickBooks Warehouse Manager supports Zebra mobile barcode scanner, helping your employees pick items for shipping, complete sales orders, update stock in real-time, and see when items run out of stock.

Features of the QuickBooks warehouse management system

What can QuickBooks Warehousing Manager do for your physical or e-commerce business? Here are some of its key features:

- Real-time stock updates: QuickBooks Warehousing Manager uses mobile barcode scanners so your employees can update, add, and delete inventory stock as they pick and pack customer orders. Real-time stock updates ensure that the inventory listed on your system matches real-world stock, eliminating discrepancies that may cause issues when selling items.

- Warehouse design optimization: In addition to increasing space efficiency, QuickBooks Warehousing Manager ensures that items that need to leave the warehouse first can be taken out easier. This is especially useful in preventing perishables from expiring.

- Labor management dashboard: A labor management dashboard ensures your team can assess employee productivity and performance by monitoring their key performance indicators (KPI). With this information, you can spot which employees require extra training and which ones perform well enough to deserve a promotion or reward.

- Inventory analytics reporting: Inventory analytics give you insight into the possible inefficiencies in your order fulfillment process, so you can address them before they become larger issues.

QuickBooks Warehouse Management benefits

Implementing QuickBooks Warehouse Manager in your business gives you many benefits, such as the following.

Keep costs in check

QuickBooks Warehouse Manager helps you make the most of your available warehouse space and labor, reduce inefficiencies, and ensure no wasted space.

By maximizing your storage space and automating manual tasks that consume valuable time, you can save money on warehouse operations and employees.

Improved inventory accuracy

Manual warehouse management is, unfortunately, prone to data entry errors, which cause discrepancies between inventory listed in the system and real-world stock.

QuickBooks Warehousing Manager uses barcodes and RFID tags to document the movement of every inventory item in the warehouse.

This increased inventory visibility is essential to prevent stock loss and eliminate inconsistencies between the system and what’s actually in the warehouse.

Enhanced security

QuickBooks Warehouse Manager uses world-class security certified by DigiCert, similar to many of the world’s top banks.

Its password-protected login, firewall, and encryption technology ensure confidential company files are safe from cyberattacks.

Inbound and outbound optimization

Inbound and outbound logistics are essential to daily fulfillment center operations.

QuickBooks Warehouse Manager increases operational visibility, reduces logistics costs, and automates manual processes to ensure both inbound and outbound processes run efficiently and affordably.

How to set up and use the Warehouse Manager in QuickBooks

Before setting up Warehouse Managers in QuickBooks Desktop, you must prepare Zebra mobile barcode scanners for your distribution center crew.

Once you have them, follow these steps:

- Install the QuickBooks Desktop application.

- Pair your Zebra scanner with your QuickBooks company file.

Your scanner is now connected to QuickBooks Warehouse Manager.

To start using the software for picking products for sale, follow this guide:

- Create a picklist according to the sales order.

- Assign a distribution center crew member to be a picker.

- Collect the items written on the pick list.

- Scan every item with the barcode scanner.

- Pack them for shipping.

Key Takeaways

A robust warehouse management system reduces costs, increases operational efficiency, and prevents products from going out of stock.

QuickBooks Warehousing Manager is one of your best WMS choices because it integrates with QuickBooks accounting software, works with a barcode scanner, and boasts world-class security.

QuickBooks Warehousing Manager FAQs

How do I set up a warehouse in QuickBooks?

To set up a warehouse in QuickBooks:

- Open the Company tab.

- Select Users.

- Select Set Up Users and Roles.

- Open your Role List tab to determine the user’s role and select Vendor Center.

- Finally, check the View Balance option under Activity Access Level.

How do I set up multiple warehouses in QuickBooks?

To set up multiple warehouses in QuickBooks, first, switch to single-user mode. Then:

- Open the Edit menu.

- Select Preferences.

- Choose the Items & Inventory menu.

- Open the Company Preferences tab.

- Check that the Inventory and purchase orders are active.

- Enable the Multiple Inventory Sites.

- Activate the Track Bin Locations within Inventory Sites option.

- Return to multi-user mode.

How do I add a warehouse in QuickBooks Online?

To add inventory tracking for a new warehouse in QuickBooks Online:

- Click the Gear icon.

- Select the Products and Services tab.

- Choose an item, then click the Edit button.

- Open the Category drop-down and choose Add New.

- Input your location name and save.

Sign up for a free trial of Method CRM today!

Image credit: Tiger Lily via Pexels