Best industrial manufacturing software for QuickBooks

Method ties all the parts of your industrial manufacturing operation together, so your team stays aligned at every step.

- Free 14-day trial

- No credit card required

- No-contract trial

Everything you need to manage customers and production in QuickBooks

1,600+ 5-star reviews don’t happen by accident. Businesses just like yours love us.

4.7/5

4.5/5

4.3/5

4.1/5

4.4/5

Tailored to the way manufacturers operate

Method adapts to the way your manufacturing business already runs, providing a clear view of every job, machine, and material, enabling better decision-making, and ensuring production remains on track.

Optimize your entire manufacturing lifecycle

Method links every part of your manufacturing process, from scheduling and materials to production and shipping. Having end-to-end insight helps you manage resources and always stay on top of all your projects.

Customizations that fit your operations

Manufacturing operations are complex and unique to each business. Tailored customizations through Method let companies of all types and sizes in the manufacturing industry set up their own processes and manage inventory to fit their exact needs.

FULLY CUSTOMIZABLE

Finally, a solution that works the way you do

You’re the expert of your business. Work with our team to build a solution that works exactly how you want it to.

And don’t worry, Method can connect to your favorite apps too:

+ more

And don’t worry, Method can connect to your favorite apps too:

+ more

Industries we support

Method offers industry-specific solutions that adapt to the way each manufacturer works, and at pricing that’s within reach for small to mid-sized teams. Customizable software makes it easier to run operations smoothly and keep quality consistent.

A unified platform for manufacturers

With Method, your sales, order, job, and customer workflows all live in one place — and you can connect the other systems you rely on through customizations and integrations. Eliminating silos gives every department the visibility they need to move faster and with confidence.

➡ Open APIs make it easy to connect your CAD, MRP, and IIoT systems for a fully connected manufacturing environment.

➡ Connects with your production, finance, and procurement tools through API-based integrations to keep key data aligned across teams.

➡ Links shop-floor data directly to your business operations for a clear view of performance and progress.

➡ Cloud-based design allows teams to access real-time information from anywhere and is ready to scale alongside you as the business grows.

Secure, scalable, and ready for growth

Method gives manufacturing businesses a secure, cloud-based platform designed for scalability. The modular design adapts as you expand users, plants, and features.

• Role-based permissions for tight control over who can view or change specific parts of the system.

• Encrypted cloud hosting keeps data protected and supports steady, reliable access throughout the day.

• Modules let you introduce new features step by step, so your team adjusts without the extra stress.

• The system keeps up as you add new product lines, locations, or staff, so you don’t outgrow your software.

END-TO-END

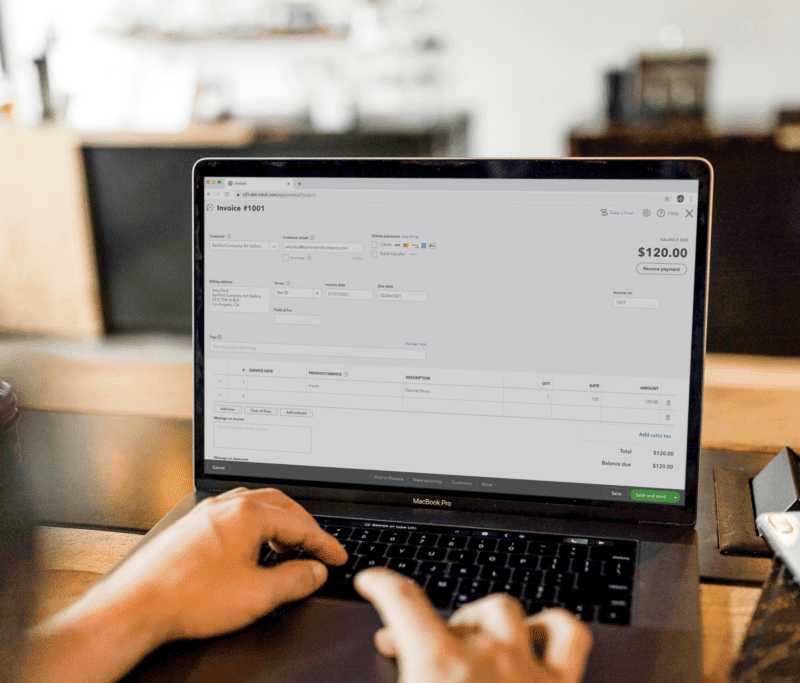

The perfect CRM for manufacturers

From estimates right down to payments, Method handles order management and tracks the customer lifecycle in one CRM platform.

Don’t see what you’re looking for?

Talk to our team about building it for you!

The #1 CRM for QuickBooks

Loved by businesses just like yours

18k+

Users trust us

2M+

Estimates created

14yrs

Helping businesses thrive

Get Started

See what Method can do for your business

Industries we serve

Additional resources

Want more industry insights?

3PL warehouse:

Your ultimate guide

Managing shipping and logistics is hard. Learn how partnering with a 3PL warehouse increases your efficiency and reduces costs.

How to run an efficient warehouse: Top tips and strategies

How to run an efficient warehouse: Top tips and strategies

Warehouse inventory control: Top 3 processes you need to automate

Is your warehouse inventory control getting out of hand? Check out this blog for the top 3 inventory processes you need to automate.

Get started with Method for manufacturers

Ready to cut the busywork, improve visibility, and keep production moving? Method’s industrial manufacturing software has the flexibility to match how your operation works.

Request a demo to see how Method keeps industrial manufacturing teams organized across quoting, production scheduling, inventory, and shipping.

Industry manufacturing software FAQs

The best software for manufacturing is the one that fits how your plant actually works — not the other way around. That’s why many manufacturers start with Method.

Method gives you a flexible front-end system for managing quotes, POs, work orders, job status, customer communication, and approvals, all synced with QuickBooks and fully customizable to your workflow.

If you also need deep inventory control or production planning, Method’s customizations and API connections make it easy to plug into your broader tech stack so every team works from the same data.

To make the right choice when it comes to industrial manufacturing software, start by understanding your core needs. Look for shop floor tracking, quoting, scheduling, QA, and a comprehensive CRM (Customer Relationship Management) software. From there, see how well each system connects with your current tools.

Choose software that supports your sector, whether aerospace, automotive, or general industrial work, and gives you room to add features later without having to rebuild your entire stack.

Cloud systems cut the cost of servers and give every plant access to the same data. Updates roll out automatically, and your team can work from any location without the need for heavy setup. It’s easier to scale across new sites, and integrations are usually built in.

With industrial manufacturing software, you get a more accurate read on your day-to-day operations thanks to clear data, experience fewer bottlenecks, and find tighter coordination across departments. It replaces disconnected tools with a single platform your team can rely on, which helps you run faster and more consistently.

Manufacturing software replaces your scattered spreadsheets with a unified system for production, scheduling, and financial management. You get better visibility into all your materials and timelines, ensuring a smoother handoff between teams. When systems tie together, you avoid errors and gain clearer insight into costs and capacity.

Before choosing any manufacturing ERP (Enterprise Resource Planning) software, it’s worth asking whether your operation even needs one. Many industrial manufacturers (especially make-to-order, custom shops, and QuickBooks users) can manage their sales, orders, jobs, and customer workflows entirely in Method without the cost or complexity of a full ERP software.

If you do need an ERP for deeper production control, here’s what to look for (and how it should work alongside Method):

- Strong production planning (routing, scheduling, materials planning)

- Inventory and purchasing management

- Support for BOMs and costing

- Shop-floor visibility or IoT connections

- Reporting that ties back to operations

In this setup, Method becomes your front-end system for everything ERPs struggle with: quotes, POs, work orders, job status, customer communication, and two-way QuickBooks sync — all fully customizable to your business processes.