How Topstitch Canvas finally found their single source of truth

The Topstitch Canvas team used to dread Fridays. It meant 10+ hours of scheduling and admin work just to align their systems, client files, and team. With Method as their source of truth, that now takes minutes.

Want to see it in action first? Take me there →

10 hrs/week of work saved

What once took 10+ hours of admin work and frustrated calls between team members and customers is now handled in minutes with fewer errors.

One source of truth

Every project detail—from CAD drawings to before-and-after photos—is stored in Method, restoring trust, eliminating errors, and keeping the whole team in sync.

Better customer experience

With a self-service portal, clients now review estimates, approve line items, pay deposits, and receive photo-backed invoices instantly—no calls or emails required.

Topstitch Canvas: Built on precision, but buried in paperwork

Since 2007, Topstitch Canvas has built its reputation on precision and craftsmanship. The company specializes in highly customized marine and exterior canvas products—everything from boat covers to outdoor enclosures—designed to withstand the elements and last for years.

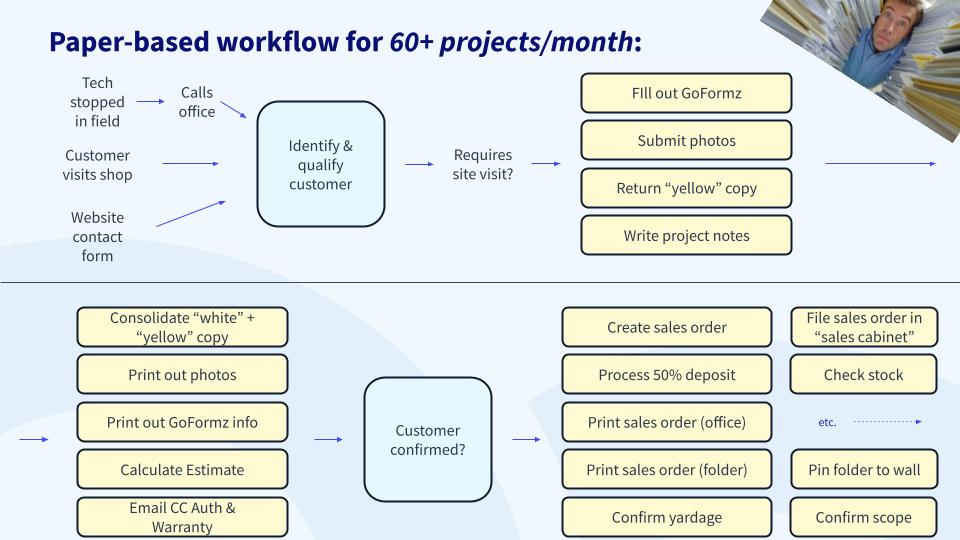

Every project is unique. Customers come to Topstitch for their expertise in heavy-duty stitching and complex, custom designs. At any given time, the team manages between 60 and 120 active projects, each taking three to six weeks to complete depending on the design requirements.

The workflow is intensive. It begins with a customer inquiry, followed by site measurements, CAD drawings, fabrication, and on-site installation. With both commercial and residential clients, no two jobs ever look the same.

This high-touch, detail-driven approach is what makes Topstitch the go-to in their market, and what has fuelled their growth. But while their products are precise, the systems they used to manage their workflows were not.

The challenge: One change could derail an entire job

Topstitch’s work is complex, with critical customer information passing through many hands between order and finished product. Without a single source of truth to manage it all, the process quickly spiralled into chaos.

This was a problem that Brooke Millan, Operations Manager at Topstich Canvas, grappled with for years before finding a solution.

New customer inquiries were recorded on sticky notes, and then turned into paper work orders. That job info lived in printed folders, with scheduling managed through Google Calendar, and estimates and invoicing handled through QuickBooks Desktop. To connect all of that, Topstitch tried a mix of apps, email chains, and group chat… But it was never enough.

The office team might have one physical copy of the work order, and the field team might have another. Any change to the work order—like a client adding a zipper or adjusting the fit—meant a scramble to update files, reprint paperwork, and hope the crew had the right version on site.

“We had folders labeled v1, v2, v3, but we had no idea which one was current or how many versions actually existed,” recalls Brooke. “It was a really terrible process.”

If something got missed—like a field team member not updating another department about a change request—the consequences were real for the business: wasted time, incorrect invoices, and products that had to be rebuilt from scratch.

The admin team spent hours managing the fallout. Fridays turned into 10-hour clerical days just to get the next week’s schedule in order. Weekly project meetings were dedicated to getting everybody on the same page—who had the latest info, what got missed, what needed fixing.

“The system wasn’t reliable. The crew would call me just to get a phone number. They learned to not trust our system at all.” — Brooke Millan, Operations Manager @ Topstitch Canvas

The solution: A platform as customizable as their work

Topstitch tried different software over the years, but nothing fit. ERPs were too rigid and not designed for the highly customized projects that the company specialized in. Project tools broke under the weight of so much customization. And none of it synced with the one system they truly relied on: QuickBooks.

What they needed was a platform as custom and dynamic as the work they delivered—one they could actually trust.

“We needed something dynamic,” Brooke explains. “Everything we tried was either too rigid, too limited, or just didn’t connect to the rest of our business.”

Step-by-step platform rollout that synced with Quickbooks Desktop

The turning point came when Brooke started digging through QuickBooks’ app marketplace. That’s where she found Method.

At first, she signed up for a 30-day trial. Within minutes, she could see the difference. A change in Method instantly synced to QuickBooks, meaning she could create and update customer files across multiple platforms at once.

“That two-way sync was huge,” Brooke said. “We’ve used QuickBooks since 2007. We weren’t about to leave it, but we needed more flexibility than QuickBooks alone could give us. Method gave us both.”

Her first call with Method’s services team sealed the deal. In a free customization session, she explained her workflow, and the rep built it live on screen. This showed her the possibilities of the platform that were far beyond what the team had initially envisioned.

Custom workflows for custom projects

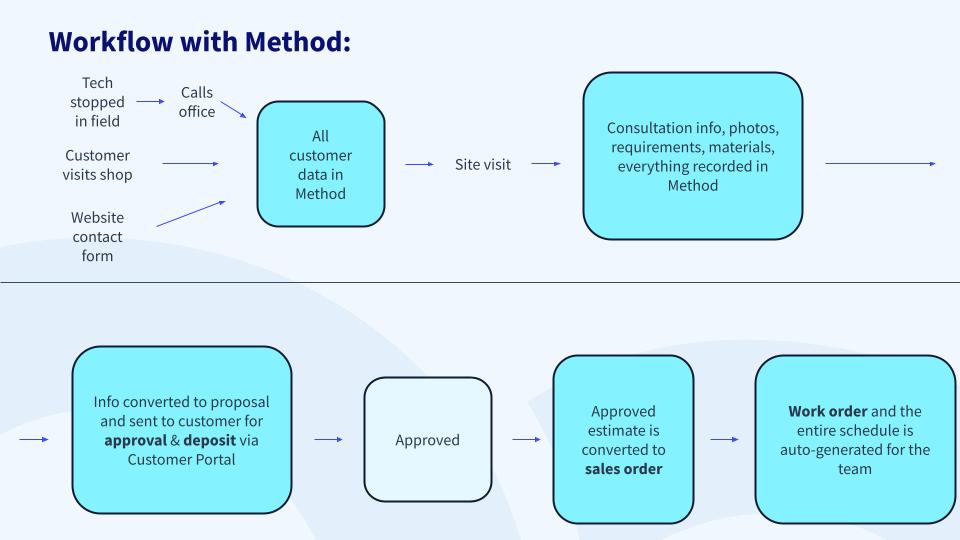

Today, Method runs through every stage of Topstitch’s process. A new inquiry becomes an opportunity in Method, replacing the sticky notes and email trails. From there, the team generates a work order for the field crew, builds the estimate, and pushes it to the customer portal for approval and deposit.

Once approved, Method automatically creates a sales order, schedules activities for each team member, and tracks the job all the way through installation. Everyone knows what they’re working on, without chasing paperwork or second guessing what they read in the system.

In addition to being a project management tool for Topstich, Method also now serves as a central hub for client files. CAD drawings, measurements, scanned forms, and before-and-after photos all live in one place—accessible to whoever needs them.

With Method’s customer portal, Topstitch clients can also login to view and approve estimates, request changes to their orders, and even access cleaning and maintenance documentation once the product is delivered.

Together, these features create a system that the team can truly rely on. Finally, the team has a single source of truth.

“Method has touched every aspect of our customer and project workflow. From the time someone inquires about a project to invoicing with final photos—it’s all in one spot now. and it’s all in real time.” — Brooke Millan, Operations Manager @ Topstitch Canvas

The outcome: a system that finally just works

With Method in place, Topstitch finally has a system as reliable as the products they deliver. QuickBooks remains the backbone for bookkeeping, but everything customer-related now runs through Method—from leads and estimates to work orders, schedules, and invoices.

Relief from scheduling headaches

Scheduling that once took 10 hours every Friday now happens in under five minutes per client file. Updating an order—something that used to mean reprinting paperwork and chasing down copies—takes a single minute.

The entire team now works from the same source of truth. Field staff log time against specific jobs, admins track progress in real time, and invoices sync instantly back to QuickBooks Desktop. No more missed updates, no more duplicate entries, and no more costly mistakes that harm the business

“We don’t need to spend so much time updating each other anymore,” Brooke emphasizes. “Everyone can see what they need, when they need it.”

Job costing and productivity reporting

The team has even implemented job costing and productivity reporting. Method creates a record in a custom job costing app for every line item on every work order. When an employee clocks into the line item on Method, job costs get automatically updated. Employees can also add materials to jobs, and the productivity percentage is immediately visible.

This used to take us hours of double-data entry in excel to get the figures—but now Topstitch uses it to audit their pricing on select items and make adjustments as needed.

Stronger client experience, scalable foundation for growth

Customers benefit, too. Through Method’s portal, they can view and approve estimates, upload photos, and access maintenance guides—all without calling the office. And if a client wants the same order they requested years ago? That information is stored in their client file in Method.

The results really do speak for themselves:

- Order updates take under 5 minutes instead of hours

- Scheduling requests completed in minutes, not days

- 10 hours saved every Friday on clerical scheduling work

- Invoices issued in real time, not delayed by missing paperwork

- Invoicing or product delivery errors are virtually eliminated, reducing the financial hit to the business

Method gave the Topstitch team the confidence that every order, every change, and every customer interaction is backed by accurate, up-to-date information.

The right match at last for Topstitch Canvas

The journey to Method wasn’t a smooth one for Topstitch Canvas. It came with years of trials, errors, and frustration for their staff and customers. But now that they’re up and running with Method, the results truly are night and day.

Client information is uploaded, updated, and synced across Quickbooks and Method is minutes. Staff know exactly what they have to do, when they have to do it. And customers receive exactly what they asked for, without having to repeat themselves or call into the office multiple times. It’s a system that finally just works.

Want to standardize your business process and set yourself up for growth? Speak to a CRM specialist to learn if Method is a fit for you.