Sign manufacturing software

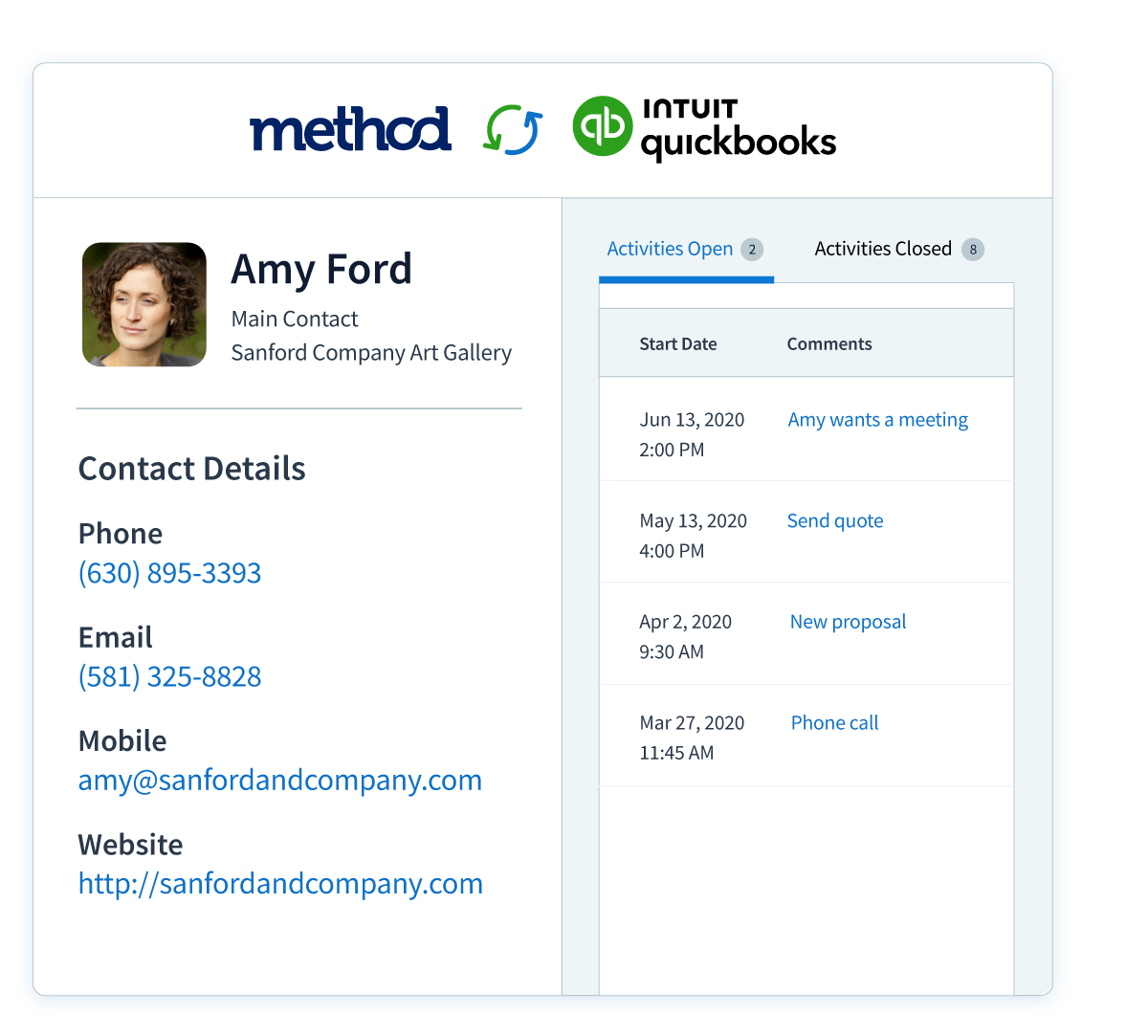

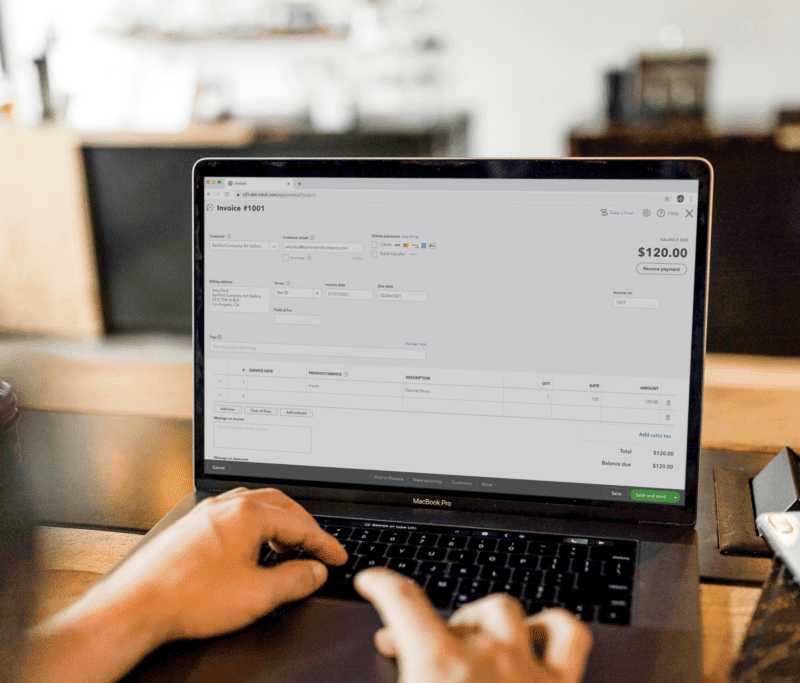

Method CRM helps sign manufacturers replace spreadsheets and disconnected tools with workflows that connect quoting, jobs, and invoicing in one system synced to QuickBooks.

- Free 14-day trial

- No credit card required

- No-contract trial

Why signage businesses need specialized software

Signs seem fairly simple, and they are, but the journey they take from manufacturing to installation is an intricate one. Each project can be completely different, involving different languages, permits, ongoing maintenance, and unique materials. Method CRM helps manage that complexity by bringing every detail into one organized, trackable system.

1,600+ 5-star reviews don’t happen by accident. Businesses just like yours love us.

4.7/5

4.5/5

4.3/5

4.1/5

4.4/5

Unique challenges for sign shops

As soon as a sign fabricator starts to grow, their sign orders and manufacturing process will become ever more complex. Generic project tools can’t keep up with custom sign work, installs, site visits, and material tracking, and they rarely sync cleanly with accounting. For instance, a shop quoting ten custom storefront signs across three cities may track materials, installs, and invoices separately, only to realize later that labor hours and LED costs were missed in the final margin. This is why sign software is so important; it takes incredibly complex and intricate moving parts and streamlines them all for the user.

No two companies operate the same way, and in the medical device industry, every company will have its own ecosystem. Method’s customization services allow you to tailor all of your workflows, forms, reports, and automation to fit your unique business needs.

Core functionality of sign manufacturing software

Estimating, quoting & pricing

- Build estimates that factor in materials, labour phases (design, fabrication, install), equipment, and permits.

- Reuse winning quotes with “same-as-except” style templates to save time on similar jobs.

- Track revisions and approvals so everyone sees the latest version.

Using Method’s cloud-based software solution, estimates sync with QuickBooks items, so costs and pricing stay aligned. Once approved, those estimates can be converted into sales orders, work orders, and invoices.

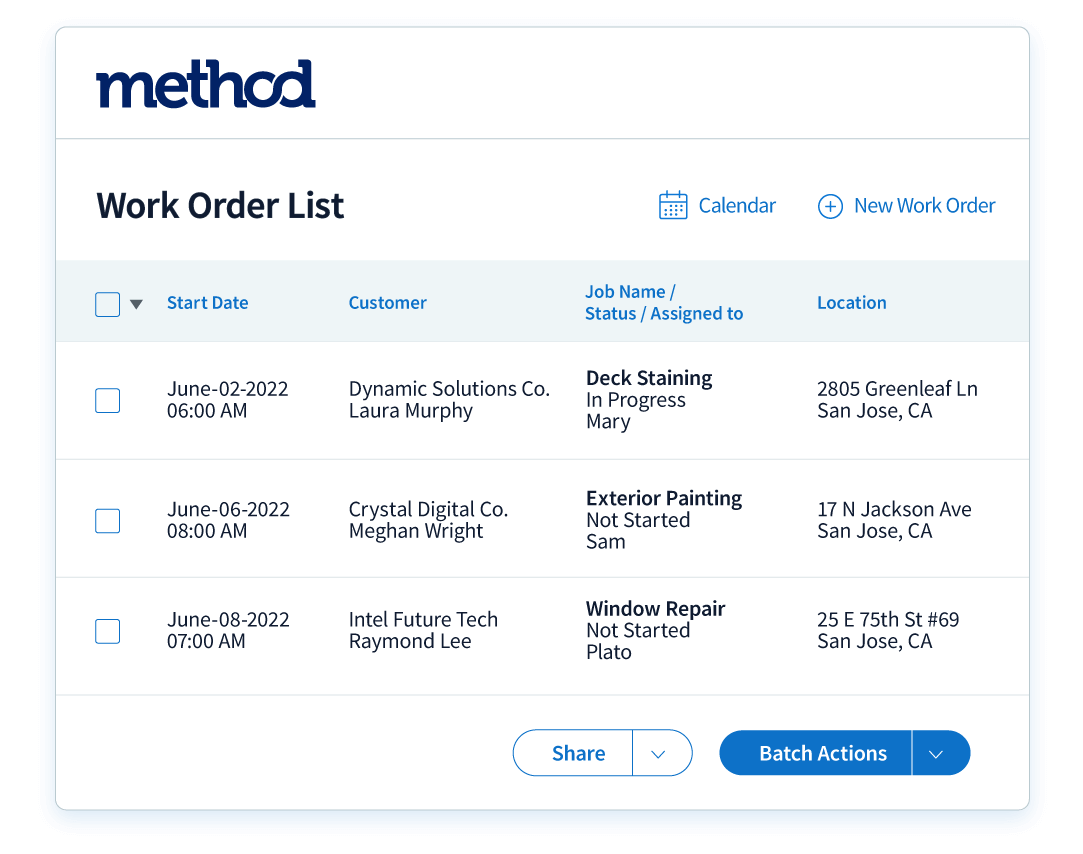

Order management & work orders

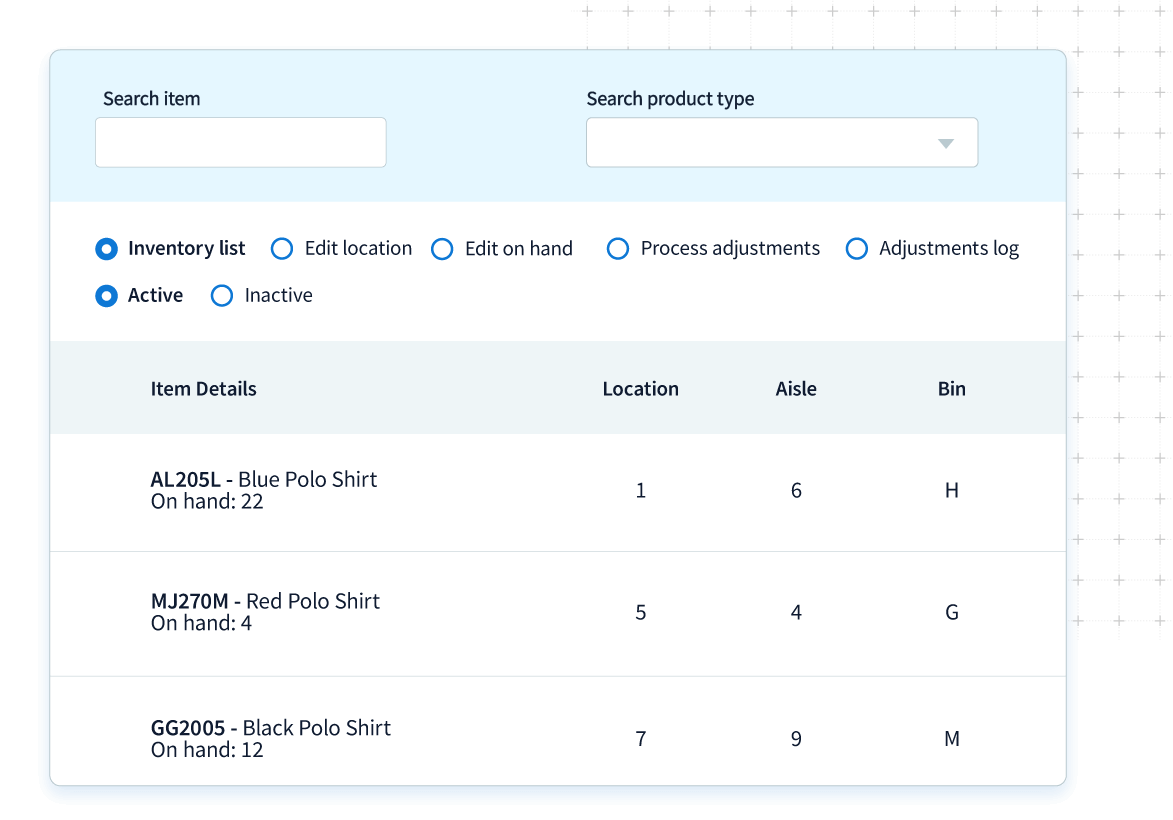

Inventory tracking & materials management

Material costs can fluctuate and impact margins, so they need to be tracked. Method helps you stay in control by:

- Syncing all items with QuickBooks so your team can quote and invoice from one unified item list.

- Tracking materials used on each work order for precise job costing and warranty support.

- Issuing purchase orders directly from approved estimates or low-stock alerts.

Production planning & shop-floor control

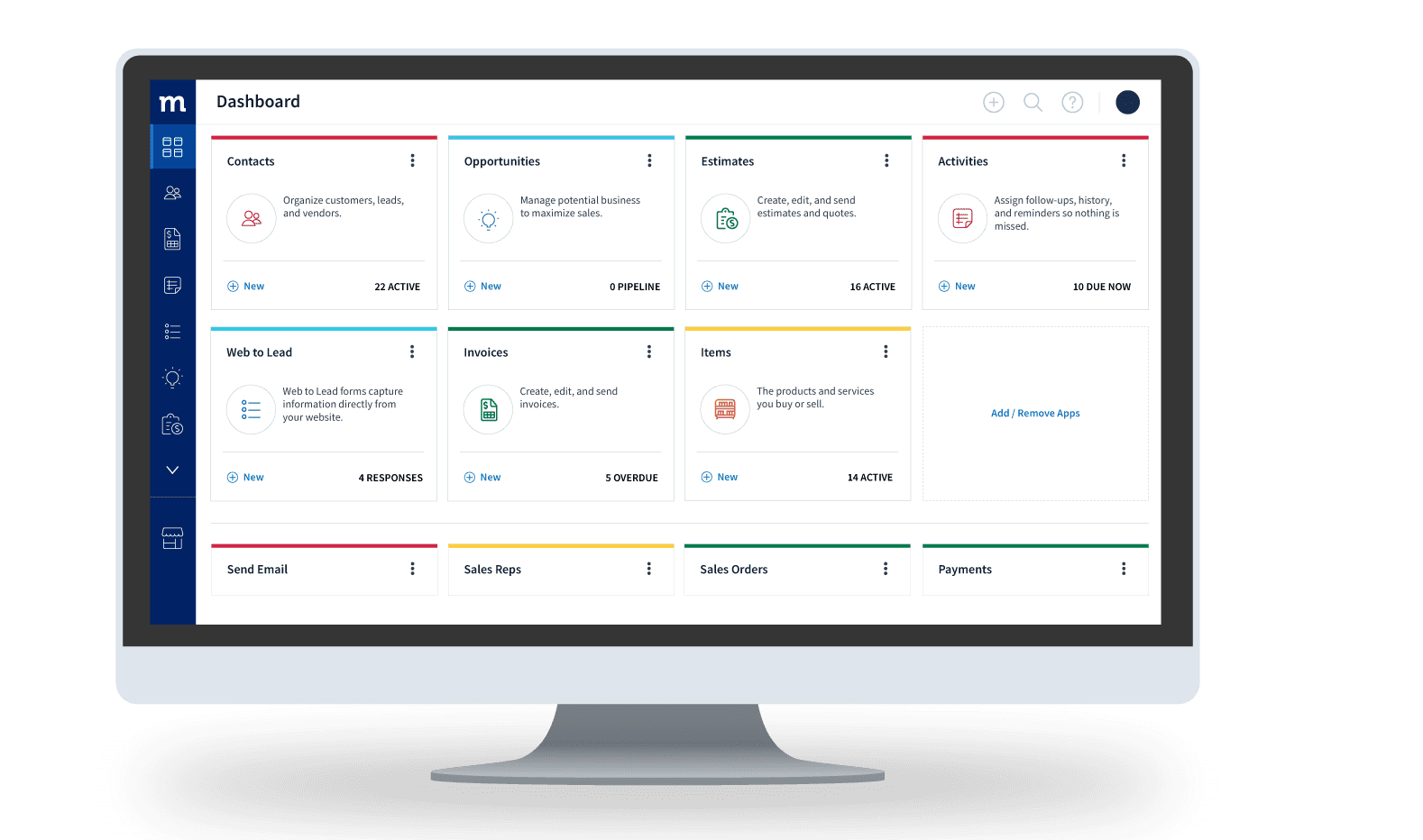

Dashboards & metrics

Method gives shop owners a real-time, configurable view of jobs, estimates, installs, and upcoming work, all connected to QuickBooks through a two-way sync.

- See what is booked, in progress, and coming up without digging through spreadsheets or QuickBooks screens

- Track job status, estimates sent vs approved, and installs scheduled from one dashboard

- Spot bottlenecks early like stalled estimates or overbooked install days

- Keep office and field teams on the same page with shared, up to date numbers

- Drill into the details when you need to, without losing the big picture

CRM, customer & project management integration

Scalability & flexibility

- Scales from small custom shops to multi-crew operations.

- Start with core workflows, quoting, work orders, invoicing, and layer in automation over time.

- Cloud access keeps designers, office staff, and installers working in the same live system.

- Custom fields, templates, and workflows adapt to your specific signage processes.

- Cost-effectiveness & ROI from automation and better customer support

Method reduces duplicate entry, cuts miscommunication, and helps avoid costly re-makes. Faster quoting and invoicing improve cash flow, while margin visibility supports better pricing and process decisions.

Typical use cases for sign manufacturing software

| Small-to-Mid Sized Sign Shops | Growing Sign Businesses |

|---|---|

Standardize quoting and pricing for common sign types. | Coordinate multiple crews, vehicles, and installation schedules. |

| Track each job from design to installation in one system. | Track materials and job costs across larger, multi-site projects. |

| See who is working on what and what’s due next. | Use approvals, templates, and automation to handle volume efficiently. |

| Invoice faster and avoid chasing missing information. | Maintain consistent branding and quality across all teams. |

How sign manufacturing software streamlines operations

Implemented well, sign manufacturing software becomes the backbone of your operation, not just another tool.

Faster quoting using templates and shared cost data.

Automated scheduling and status updates instead of manual calls and emails.

Fewer errors thanks to consistent workflows and real-time data.

Better resource allocation using dashboards that show workloads and bottlenecks.

Less material waste with integrated inventory and purchasing.

Customizations for sign manufacturing workflows

Every sign shop works differently. With Method, shops reuse templates and custom fields for common sign types and installs, while workflows automatically generate complete job records and trigger purchasing as work moves from design to install.

Below are some typical needs for sign fabricators:

| Customization Need | How Method Supports It |

|---|---|

| Estimating templates | Reusable templates for channel letters, monuments, wraps, wayfinding, and more. |

| Custom fields | Track substrates, LED modules, labour phases, install options, permits, and hardware. |

| Shop travelers/production packets | Auto-generate build sheets directly from approved work orders. |

| Workflow stages | Trigger notifications and stage changes across design, fabrication, paint, and installation. |

| Purchasing automation | Create POs from jobs and support warehouse-level purchasing. |

| Inventory visibility | Pair with inventory tools for multi-warehouse tracking and material planning. |

| CAD handoff | Attach drawings, PDFs, and design files directly to jobs and work orders. |

| Reporting & dashboards | Customize production, scheduling, and margin insights with Method’s report designer or BI tools. |

FULLY CUSTOMIZABLE

Finally, a solution that works the way you do

You’re the expert of your business. Work with our team to build a solution that works exactly how you want it to.

And don’t worry, Method can connect to your favorite apps too:

+ more

And don’t worry, Method can connect to your favorite apps too:

+ more

The #1 CRM for QuickBooks

The manufacturer CRM loved by businesses just like yours

18k+

Users trust us

2M+

Estimates created

14yrs

Helping businesses thrive

We’ve doubled our revenue in the past three years. Without Method, it would have been nearly impossible.

Glenn Taylor

CEO at Container One

How to choose the right sign manufacturing software

Everyone will have a different process based on their needs and business philosophy for choosing the right software, but below is a checklist of points to consider.

Sign shop selection checklist

Shop size & complexity : Small, growing, or multi-site? How many jobs per month?

Workflow coverage: Do you need quoting only, or full coverage from design to installation and service?

Integration needs : Must it sync with QuickBooks, CAD, storage tools, or other systems?

Budget & ROI : What can you invest now, and what savings or extra capacity do you need in return?

User experience: Can shop floor staff and field crews use it easily on desktop and mobile?

Deployment model: Cloud vs on-premise, and whether you need remote access for crews.

Customization: Do you have unique sign types, materials, or install logistics that require flexible templates?

Reporting needs: Which KPIs (lead times, job margin, install completion, re-work) matter most?

Get Started

See what Method can do for your business

Industries we serve

Sign manufacturing software FAQs

Yes. Method CRM offers real-time, two-way QuickBooks sync so estimates, work orders, and invoices all share consistent customer and item data. You can also attach CAD files or link drawings directly to jobs, and you can even use it with a digital sign

By connecting quoting, work orders, inventory, and invoicing in one system, sign software eliminates duplicate data entry and manual handoffs. Automated workflows, reusable templates, and real-time QuickBooks sync help sign shops save time, reduce errors, and improve overall operational efficiency as job volume grows.

Yes. Modern sign manufacturing software is designed to be user-friendly and time-saving for both office staff and field crews. With clear work orders, shared calendars, mobile access, and simple status updates, teams can quickly see what’s due next without navigating complex systems, saving time across quoting, production, and installation.

Sign projects involve many moving parts, from materials and labor to installs and timelines. Method CRM brings quoting, jobs, and invoicing into one connected system synced with QuickBooks, giving sign businesses clear, real-time visibility into costs, workloads, and job status. This centralized view helps improve decision-making without relying on spreadsheets or disconnected tools.