What Sales, Order & Inventory Automation Should Look Like in 2026

Manual processes once worked for smaller teams. Today they expose your business to stock-outs, delayed cash flow, and unnecessary labor costs. Two-thirds of SMB leaders now say automation is essential to their operations—not optional.

This article summarizes our recent panel discussion with:

- Lance Brandow – Owner & President @ Brandow Consulting

- Ryan Woodbury – Strategic Partnerships Manager @ Fishbowl

- Nelson De Miranda – Sr. Director of Sales & Services @ Method

- Hosted by Matas Pranckevicius, Content Lead @ Method

If you’re looking for the quick automation self-assessment that was shown during the webinar, you can grab it here:

Their advice focuses on fixing the right bottleneck first, choosing tools that integrate with QuickBooks, and measuring results before expanding the project.

The cost of manual work

- Global stock-outs and overstocks erode about US $1.77 trillion in retail revenue each year.

- Large “big-bang” ERP projects fail as often as they succeed, mainly because workflows are undocumented and staff are not prepared for the change.

Replacing key hand-offs with digital workflows protects gross margin and shortens the order-to-cash cycle without forcing a full ERP migration.

Identifying the real bottleneck

Lance Brandow applies Eliyahu Goldratt’s Theory of Constraints, as documented in the novel The Goal:

- Document one complete order from quote to cash.

- Locate pile-ups — orders waiting in a queue, data re-entered, or inventory waiting for inspection.

- Resolve one constraint, measure the impact, then move to the next.

Typical high-ROI starting points:

- Manual re-keying of web orders

- Spreadsheet-based purchasing decisions

- Paper pick lists that delay shipping

Two implementation examples

Basin Upfitting

- Problem: Thousands of SKUs managed in spreadsheets; frequent stock-outs.

- Solution: Fishbowl inventory management integrated with QuickBooks.

- Result: Inventory now turns every 30 days and revenue is on track to double.

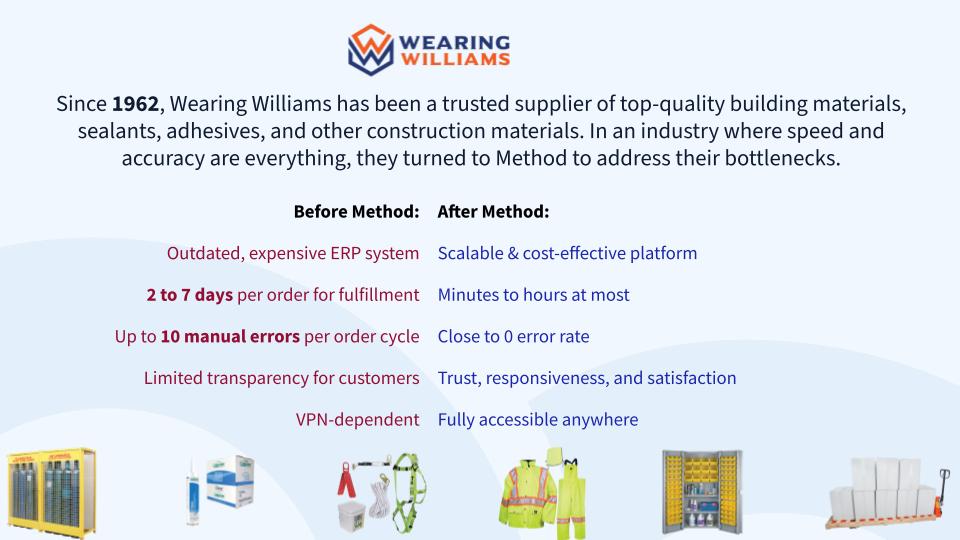

Wearing Williams

- Problem: Seven-day delay between material pickup and invoicing.

- Solution: Method customer portal captures signatures and triggers automatic invoicing.

- Result: Same-day invoices and clear chain of custody, improving cash flow.

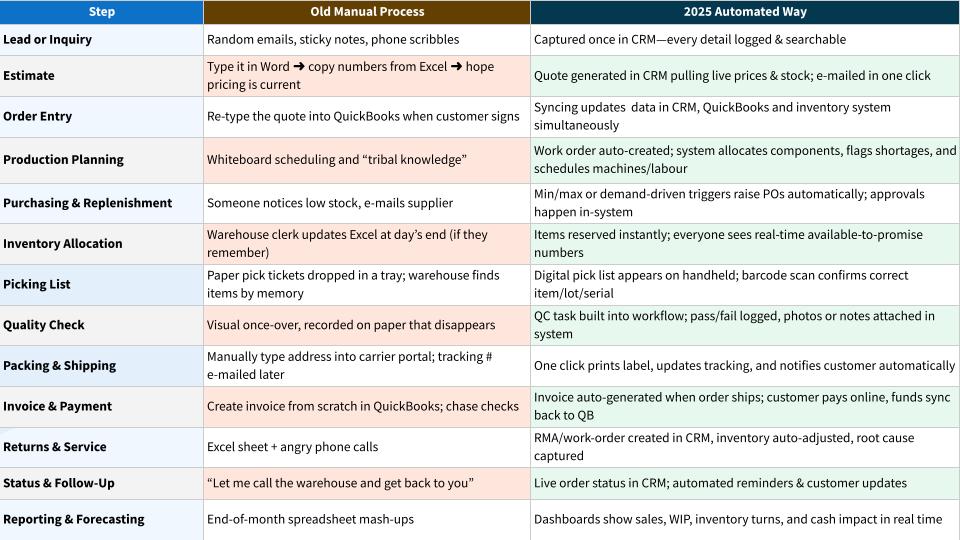

What an automated workflow looks like

| Step | Manual Approach | Automated Approach |

|---|---|---|

| Sales capture | CSR re-keys orders | API pushes orders into Fishbowl and Method |

| Inventory promise date | Spreadsheet lookup | Real-time availability with auto-generated purchase orders |

| Pick & pack | Paper pick list | Mobile barcode scanning, lot/serial capture |

| Shipment tracking | Copy/paste into carrier sites | Integrated label printing and automatic tracking updates |

| Invoicing | Hand-typed in QuickBooks | One-click invoice with embedded payment link |

Each automated hand-off shortens lead time, reduces errors, and keeps QuickBooks as the financial system of record.

Common implementation risks

- Automating flawed processes: Validate and revise the workflow before integrating it.

- Skipping a test environment: Clone your data, verify results, then go live.

- Neglecting change management: Train users early and show quick wins to maintain adoption.

Next steps: how we can help

If you are ready to reduce manual work and improve inventory accuracy, choose the option that fits your situation:

- Start a 14-day free trial of Method CRM – Test two-way QuickBooks sync and custom workflows with your own data.

- Schedule a Fishbowl demo – See demand forecasting, automated purchasing, and mobile barcoding in action.

- Book a workflow consultation with Brandow Consulting – Map your current process, identify the primary constraint, and receive a phased implementation plan.

Each service is designed for SMB budgets and can be deployed without replacing QuickBooks. Contact us today to begin a pilot and measure results within a single fiscal quarter.